Safurex®

Improve the reliability and performance of your urea plant

The Challenge

Urea industry processes take place at high temperatures and pressure, and ammonium carbamate is highly corrosive. Therefore, the high-pressure (HP) synthesis equipment and parts have to be manufactured from strong, light and corrosion-resistant materials.

The Solution

Stamicarbon partnered with Sandvik in the 1990s on the development of Safurex®, a super duplex stainless steel specially designed to eliminate corrosion in fertilizer plants.

It effectively tackles active ammonium carbamate corrosion, chloride stress corrosion cracking, condensation corrosion and other corrosion problems typically occurring in fertilizer plants.

By applying Safurex® materials of construction in your urea plant, you receive the following advantages:

- Resistance to main types of corrosion in HP urea equipment

- Independence of passivation air

- Improved mechanical properties and excellent weldability

- Reduced weight of equipment

- Reduced need for inspection and maintenance

- Highest reliability (more than 1.5 million years of total combined on-stream time without a tube rupture) and longer equipment lifetime

- Improvement of urea plant process performance

- Higher flexibility in plant operations (i.e. long block-in time)

- Less vulnerable to upset conditions

Would you like to learn more about Safurex® steels?

Infinity, Degree & Star

Different equipment items in the HP synthesis section require dedicated material applications to ensure optimal performance.

That’s how the three grades of Safurex® materials were developed:

- Safurex® Infinity is the standard super duplex stainless steel used in the HP synthesis section of urea plants.

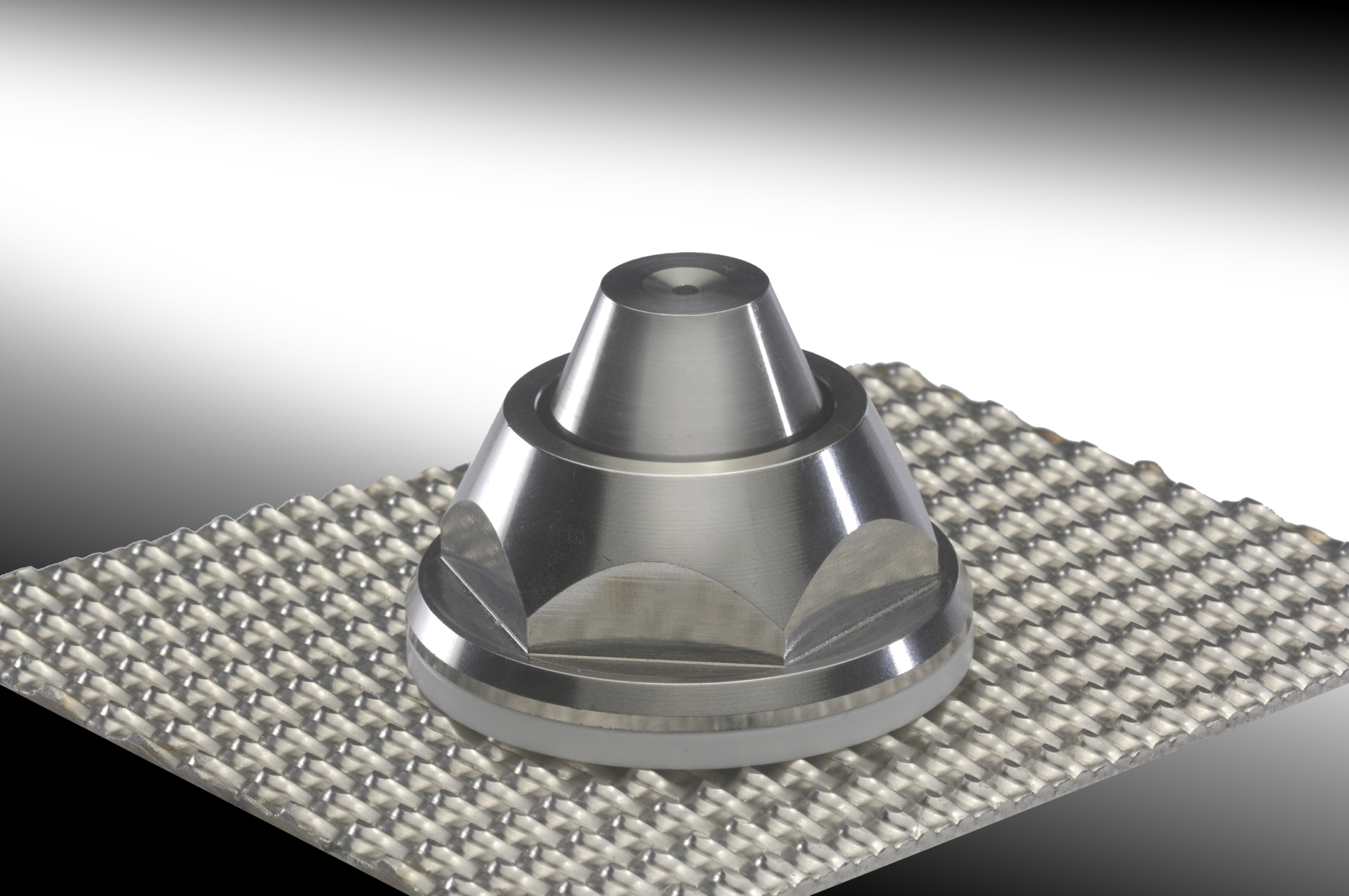

- Safurex® Degree is fabricated via the Hot Isostatic Pressing (HIP) method, which allows for enhancement of the material’s corrosion resistance and mechanical properties at low temperatures. It is used in HP valve bodies and liquid dividers in the HP stripper.

- Safurex® Star is designed for application in equipment with the most demanding process conditions, such as heat exchanger tubes in the HP stripper for all stripping processes.

Sustainability

Apart from its durability and corrosion resistance – which are crucial for ensuring safe and efficient plant operations – Safurex® materials are also manufactured with sustainability in mind by melting the steel in an electric arc furnace with electricity produced from fossil-free sources and using a high percentage of recycled materials in the melt. As a result, the production of Safurex® has one of the lowest carbon footprints in the industry.

Safurex® Materials for Non-Stamicarbon Plants

Stamicarbon has installed HP equipment made from Safurex® steels in several non-Stamicarbon thermal and CO2 stripping plants. Examples include:

• HP strippers

• HP carbamate condensers, including kettle-type

• HP urea reactors

• HP piping and valves

• Liquid dividers

• Mixing tees

Learn more about products and services for non-Stamicarbon plants

Safurex® Products and Services

Stamicarbon has built over 400 pieces of equipment with Safurex® material and has used it as a standard material for all HP equipment and piping in Stamicarbon urea plants since 2003. During this time, active corrosion or rupture of heat exchanger tubes made from Safurex® has never been observed.

The total combined on-stream time of heat exchanger tubes in HP strippers, HP carbamate condensers, HP scrubbers, pool condensers and pool reactors installed by Stamicarbon is far over 1,5 million years without tube rupture. This implies a failure on demand of less than 10-7, which is a spectacular achievement in the fertilizer market.