Achieve better control of the process with high-pressure valves

The Challenge

Valves are essential to a plant's control, shutdown and isolation philosophy.

Control and ON/OFF valves in a urea plant's high-pressure (HP) synthesis section are subjected to the highly corrosive carbamate process medium and severe operating conditions like two-phase flow. Flashing can cause problems and lead to damage to the valve components.

Under these conditions, if a valve is not performing optimally, it can negatively impact the overall plant performance and cost of ownership, as the repairs or replacement can only be done during the plant shutdown.

Therefore, it is extremely important to select the correct valve fabricated from the most suitable and reliable material for the service.

Stamicarbon has developed a long-term partnership with qualified valve suppliers and a world-class steel manufacturer, enabling us to offer high-quality valves for urea plants made of corrosion-resistant E-type material.

We have developed E.I-type duplex steel manufactured using the Hot Isostatic Pressing (HIP) method, which is highly suitable for control valve components like the body and seat.

This material allows valves to perform well in severe environmental conditions and to meet impact strength properties at MDMT (Minimum Design Metal Temperatures) as low as 35°C, which are sometimes specified.

The microstructure of E.I-type material is very fine and equiaxed. The austenite spacing (grain distance) is smaller than 14 µm. Applying this steel to the valve body significantly reduces cross-cut end attack, improving overall corrosion resistance.

Additionally, impact strength is expected to improve at lower minimum design metal temperatures.

Angle valves are characterized by the inlet and outlet ports perpendicular to each other, while globe valves have several advantages:

- Excellent control of liquid services in HP applications

- High flow rate with low pressure loss

- Good shut off capability

- Easy to machine or resurface the seats

- Quite simple maintenance

Stamicarbon can also supply other valve types, like butterfly valves or straight globe valves, to maintain compatibility with the connecting pipelines, enabling installation of the valve without modifications.

Manual (mechanical) valves

Manual valves allow the plant operator to control the process in the synthesis section by manually opening and closing the valve.

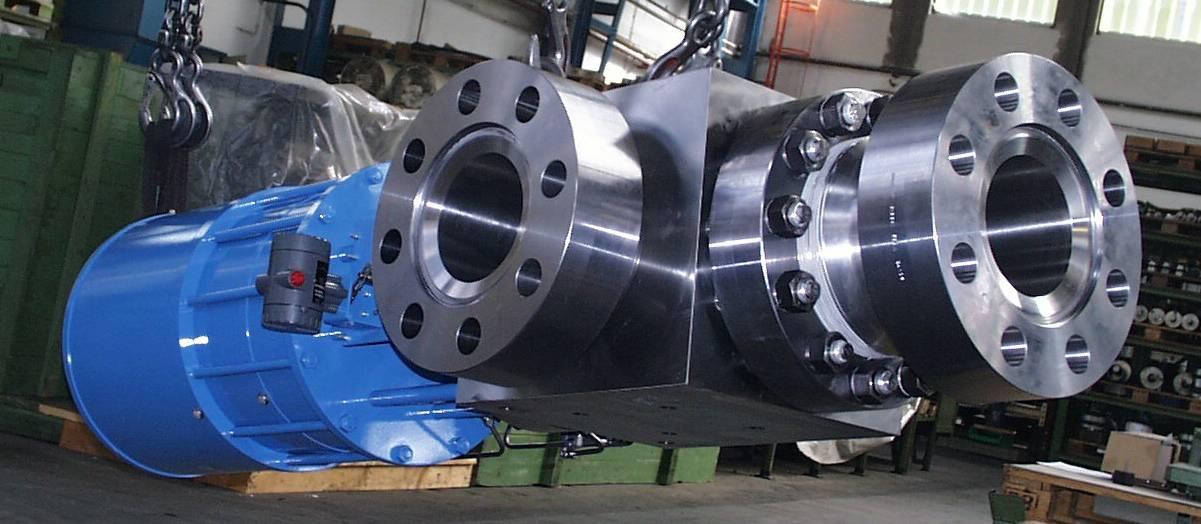

Control & ON/OFF valves

Control & ON/OFF valves have a pneumatic actuator that provides the valve (stem) movement, eliminating the need for manual opening and closing of the valve. Control valves also have a valve positioner that increases or decreases the air load pressure on the actuator, placing the valve in the correct position.

Butterfly control valve

Butterfly control valve

Safety valves

Safety valves (also known as pressure safety valves (PSV) or pressure relief valves (PRV)) are designed to protect your equipment and piping in the event of overpressure.

During normal plant operation, pressures remain below the maximum allowable working pressure (MAWP). However, if pressures exceed this limit, safety valves will open, relieving excess pressure from the equipment and preventing rupture.

After normal conditions have been restored, the safety valve recloses, preventing further release of fluid.

The number of safety valves needed in the system depends on plant capacity and flange rating. The first valve will have pressure set according to the design pressure of the protected equipment. Next safety valves will have higher set pressures.

Stamicarbon only fabricates valves and valve components at qualified and reputable manufacturers who have experience with urea equipment and E-type material. During the entire manufacturing process, Stamicarbon is involved in the Quality Assurance / Quality Control (QA/QC) to guarantee the equipment's high quality and reliability.

Contact us for more information about HP valves.