Your ammonia growth, grounded in our nitrogen experience!

The challenge

Ammonia is one of the key building blocks widely used in fertilizers and various industrial processes. Its role, however, is rapidly evolving. As a highly efficient hydrogen carrier, ammonia is becoming a key enabler in the energy transition, particularly for decarbonizing hard-to-abate sectors. Meanwhile, the global demand for ammonia is expected to rise significantly.

The question isn't whether consumption will grow, but whether it will grow in line with the global population and economic expansion or accelerate even faster as it becomes an indispensable component of the low-carbon economy.

The Solution

With over 75 years of expertise in nitrogen fertilizer technologies, Stamicarbon offers trusted solutions for efficient and scalable ammonia production. Our ammonia technologies portfolio includes two distinct designs, each tailored to specific project scales, feedstock types, and sustainability goals.

Whether your priority is small-to-medium scale production from renewable electricity or large-scale ammonia from fossil sources with carbon capture integration, we have the solution to match your needs.

Need more details and tailored solutions for your ammonia plant? Contact Our Experts

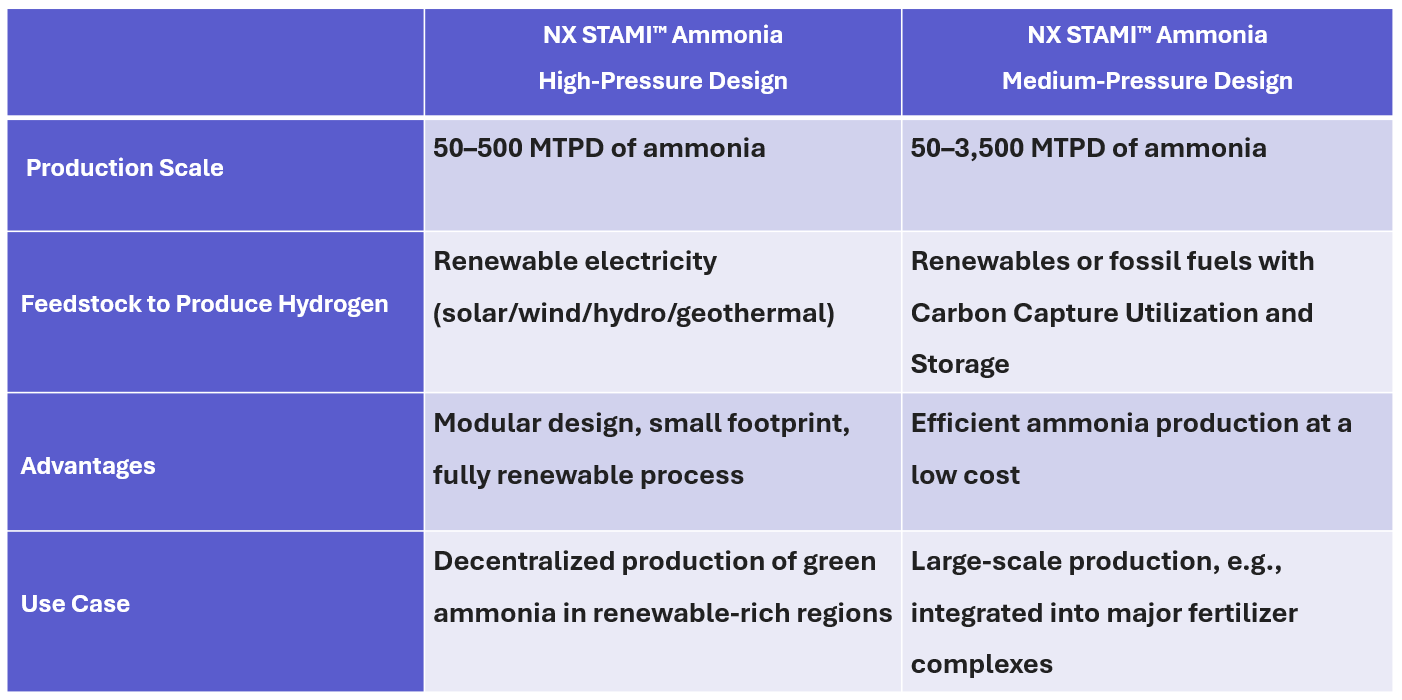

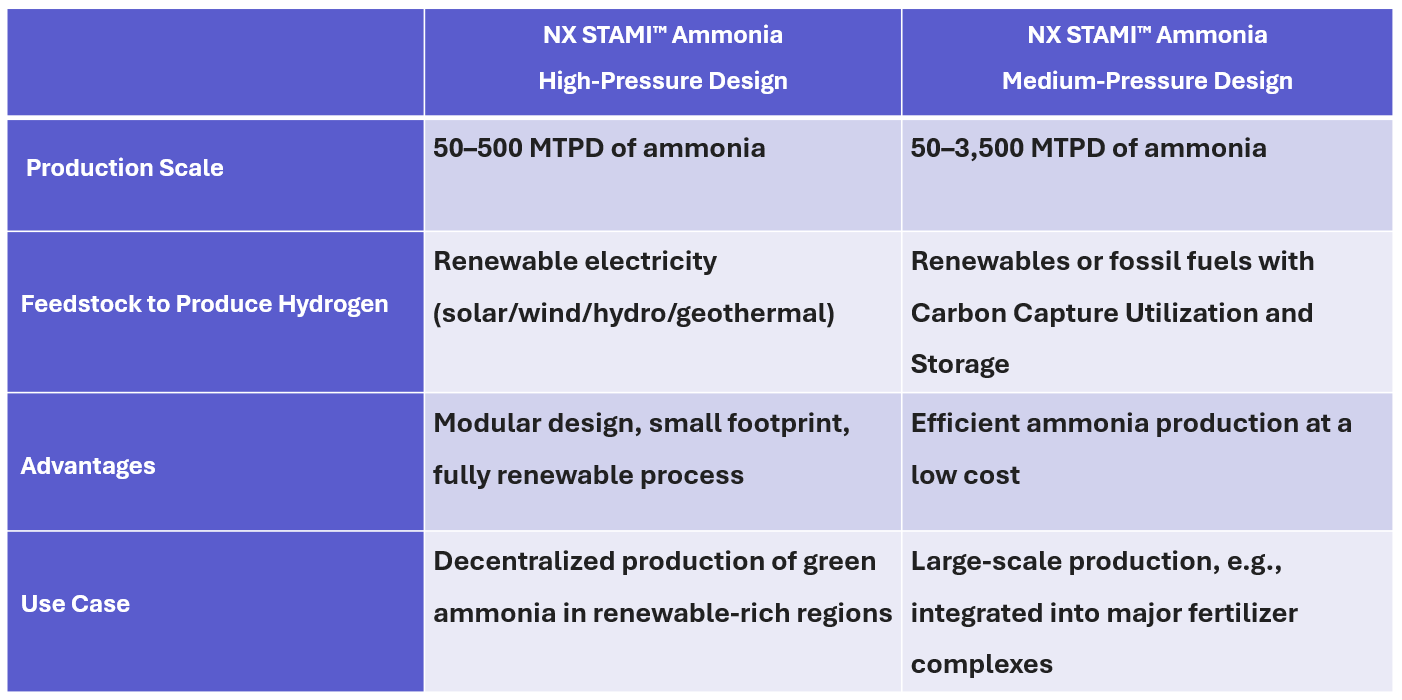

NX STAMI™ Ammonia at a Glance

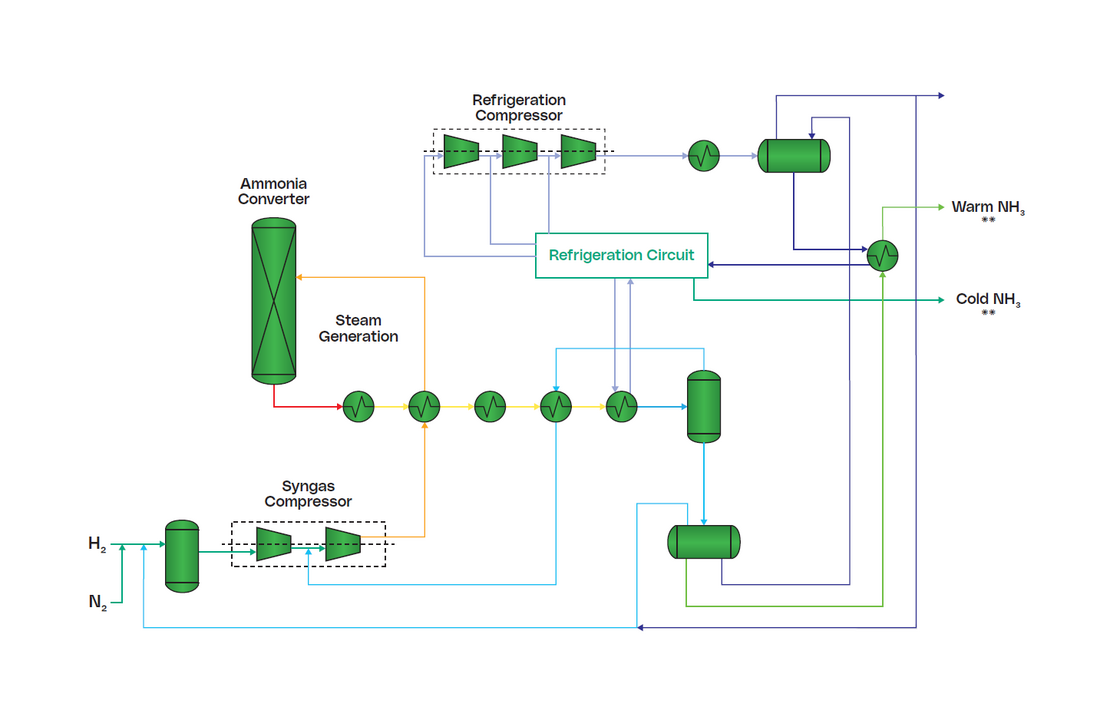

NX Stami™ Ammonia offers medium and high-pressure technologies for small to large-scale ammonia production. These technologies cover 50-500 and 50-3500 MTPD ammonia, using renewable electricity (solar/wind/hydro/geothermal), as well as renewables or fossil fuels with carbon capture utilization and storage.

The high-pressure design is modular with small footprints, and the medium-pressure design supports efficient ammonia production at a low cost. These technologies are suitable for decentralized production of green ammonia or large-scale production, e.g., integrated into major fertilizer complexes.

Solutions for Large Capacity Ammonia Plants

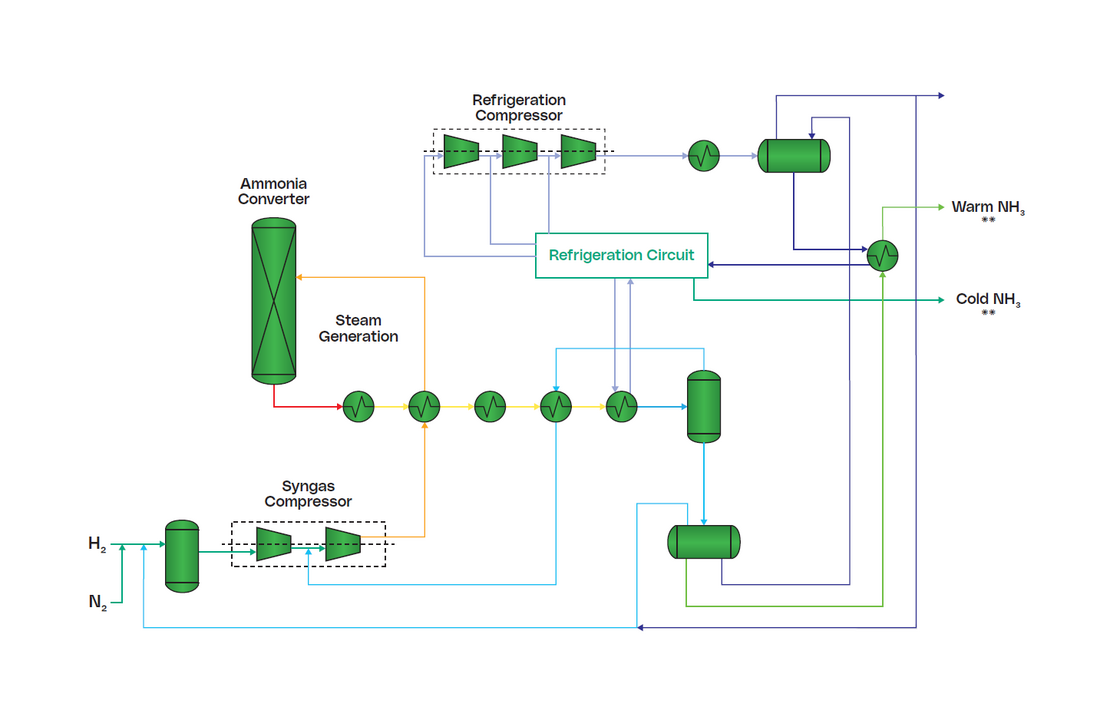

To meet the growing demand for low-cost and high-efficiency ammonia production, Stamicarbon offers the NX STAMI™ Ammonia Medium-Pressure Design.

Designed for capacities ranging from 50 to 3,500 MTPD, and scalable to even larger sizes, this process provides flexibility to match specific customer needs.

With more than 45 industrial references, NX STAMI™ Ammonia Medium-Pressure Design is a proven and cost-effective solution for conventional ammonia production.

NX STAMI™ Ammonia Medium-Pressure Design features a multi-bed, radial-flow reactor with a low-pressure drop configuration. This has been optimized to allow high per-pass conversion with the minimum possible catalyst volume and can be customized based on operating variables.

The system is notable for its superior temperature control in the first bed, allowing for a more efficient converter operation and a longer expected catalyst lifespan.

Green Ammonia Production

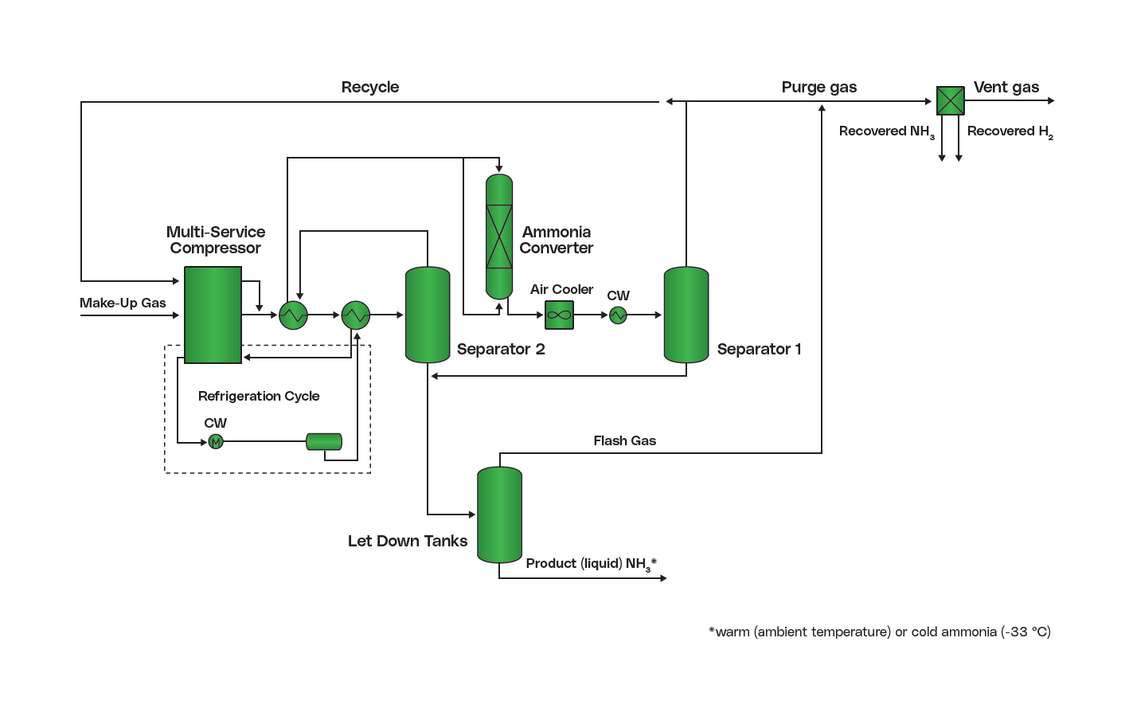

To enable ammonia production from renewable energy sources with minimal environmental impact, Stamicarbon also offers the NX STAMI™ Ammonia High-Pressure Design, focusing on sustainable ammonia production.

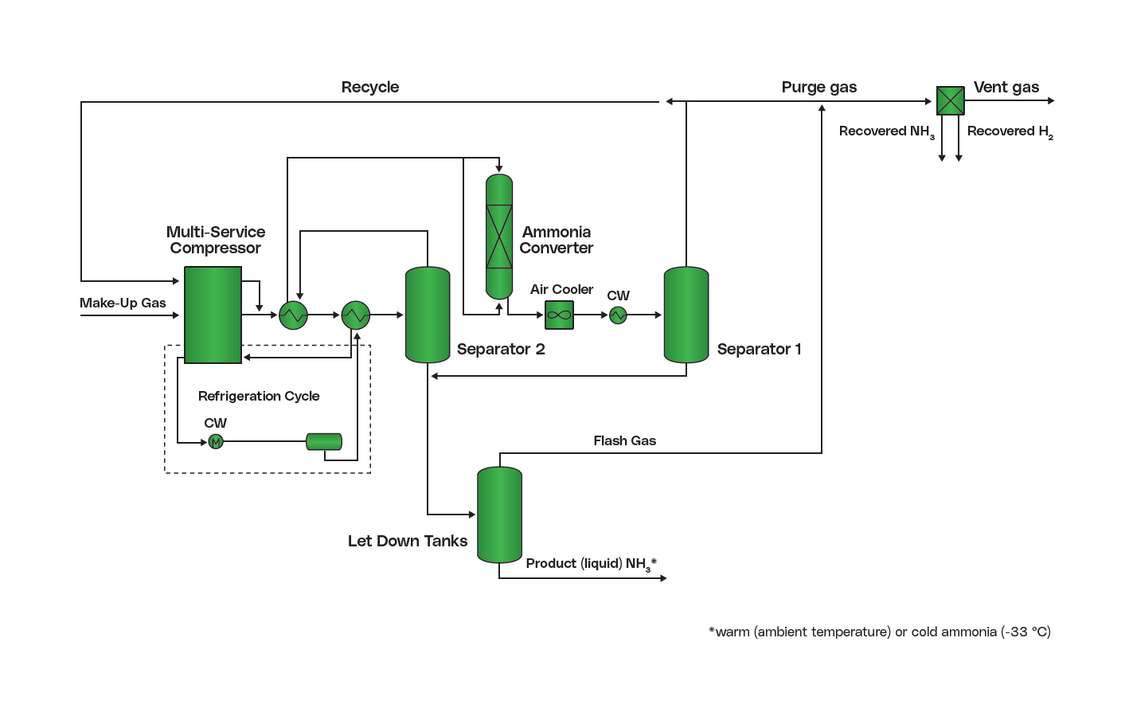

Designed for small- to medium-scale green ammonia plants with capacities from 50 to 500 MTPD, this technology features a modular setup and compact footprint, making it ideal for decentralized applications.

Operating with a single reciprocating compressor minimizes equipment requirements and delivers substantial CAPEX savings.

With four plants already in operation, NX STAMI™ Ammonia High-Pressure Design has the most substantial reference base in the sub-500 MTPD segment, more than any other licensor.

The ammonia synthesis loop operates at a high pressure, increasing conversion efficiency while reducing the need for costly refrigeration systems. The ammonia converter used in this process features a single axial flow catalyst bed design. Heat exchange tubes submerged in the catalyst bed allow excellent temperature control, preventing adverse effects such as catalyst sintering.

The process flow begins with make-up gas, a mixture of hydrogen and nitrogen from an upstream electrolyzer and nitrogen generation unit. This gas is compressed in an electrically-driven reciprocating compressor to over 300 bar, and the recycle stream also recompressed to the same pressure.

The high-pressure synthesis loop allows single-stage ammonia condensation using cooling water, eliminating the need for a refrigeration compressor.

FAQ

How can I produce ammonia with the highest efficiency?

NX STAMI™ Ammonia technologies are designed for optimization. They are cost-effective, with competitive pricing across all plant sizes.

• Medium-Pressure Design offers high per-pass conversion and a longer catalyst lifespan.

• High-Pressure Design increases conversion efficiency and reduces refrigeration needs.

Therefore, both technologies contribute to optimized production.

How can I produce ammonia at low cost and high yield?

How can I reduce the carbon footprint in my ammonia plant?

We offer sustainable options for producing ammonia. Through our high-pressure design you can produce green ammonia from renewables (carbon-free) and by integrating CCUS with the medium-pressure design you can produce low-carbon conventional ammonia, known as blue ammonia.

For more information:

• Listen to our technical podcast about green ammonia and its applications in the fertilizer industry

Can I integrate Stamicarbon's ammonia technologies with my other production lines?

Yes, Stamicarbon's technologies offer integration with water electrolyzers, CCUS, and Stamicarbon’s nitric acid and urea technologies.

For more information, contact our ammonia experts for tailored ammonia solutions.

How do I decide between Stamicarbon Ammonia technologies?

Choose the design based on plant size, feedstock and sustainability goals.

• If you need a large‑scale conventional plant (50–3,500 MTPD) or plan to use fossil feedstocks with carbon capture, the medium‑pressure design offers proven efficiency and flexibility.

• For small‑to‑medium‑scale green‑ammonia projects (50–500 MTPD) that use renewable hydrogen, the high‑pressure design provides modularity, lower CAPEX and simplified operation.

How can I get personalized advice or a customized solution for ammonia production?

Stamicarbon offers feasibility studies, project development support, and licensing for ammonia plants.

Contact our experts for a custom ammonia plant design that matches your feedstock, energy source and capacity requirements.

What references or track record does Stamicarbon have in ammonia?

The NX STAMI™ Ammonia Medium-Pressure Design has more than 45 industrial references worldwide, and the High-Pressure Design has 4 plants already in operation, demonstrating its widespread use.

Explore global ammonia projects using Stamicarbon ammonia technologies.