Distributed ammonia and sustainable fertilizer production

By Deepak Shetty, Business Development Manager at Stamicarbon

Nitrogen-based fertilizers are essential for feeding the growing world population, and their availability and affordability for farmers are critical for ensuring food security. Depending on the region and the socio-economic situation in the world, fertilizer availability differs. Even before the escalation of the conflict in Eastern Europe, global fertilizer supplies were impacted by COVID-19 disruptions, labor shortages, high fertilizer consumption in Southeast Asia, and general price volatility.

Despite being necessary for feeding the world, fertilizers produced via traditional manufacturing routes also have a negative environmental impact, contributing to global greenhouse gas emissions. It is estimated that in 2018, synthetic nitrogen fertilizers contributed to 2.1% of the world’s greenhouse gas emissions1. This is not sustainable if we think about the future, where technologies and knowledge should be aimed at producing fertilizers with minimal environmental impact, and one key step to address this challenge is clean ammonia.

Different colors of ammonia

The most common ammonia production route uses the Haber-Bosch process of high-pressure ammonia synthesis, invented in the early 1900s. For economic reasons, hydrogen – a building block of ammonia – is derived from fossil fuels through either steam reforming (gray ammonia) or coal gasification (brown ammonia). Neither gray nor brown ammonia is sustainable due to the high energy intensity of the process and high carbon dioxide emissions from fossil fuels.

Blue ammonia is based on the grey or brown process, but the carbon dioxide generated is sequestrated and stored, not emitted into the atmosphere. This already offers a more sustainable production route.

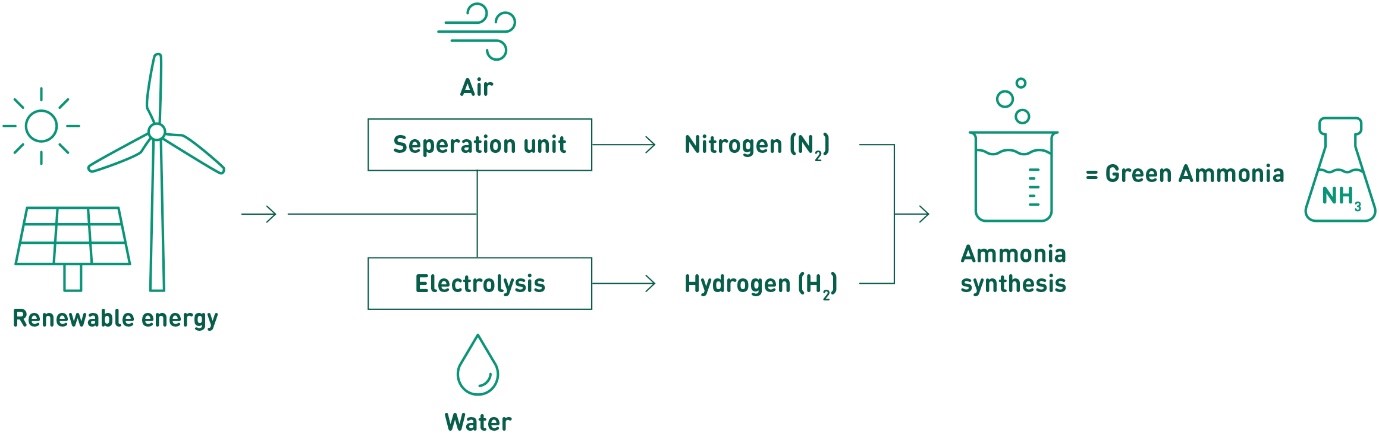

Green ammonia presents a viable, sustainable solution that eliminates carbon from the process entirely. The green ammonia process combines renewable electricity with an electrolyzer to produce hydrogen and derives nitrogen from the air using a nitrogen generation unit. Using the resulting green ammonia as a feedstock for nitrate-based fertilizers like ammonium nitrate and its derivatives results in carbon-free fertilizers, or, if the carbon component is available from a circular source, still for urea. Green ammonia can then lower the carbon footprint of the fertilizer industry but can also similarly contribute to other areas such as (shipping) fuel and energy markets.

Local production of fertilizers with renewables

The availability of renewable energy acts as the driving force for green ammonia production. Renewable energy resources are distributed more evenly around the globe than fossil fuels, and the type of available renewable energy depends on location. Countries where these resources are in ample supply can become more self-sufficient in fertilizer production. This, in turn, would reduce problems caused by supply chain disruptions and price fluctuations.

Let’s look at Africa as an example of a region with abundant renewable energy resources that can be used to increase local fertilizer production and strengthen food security. The high availability of solar energy resources in Africa enables the production of green hydrogen/ammonia on a large scale.

According to a 2022 study, it is possible to produce more than 50 Mt of green hydrogen per year using solar energy in Africa by 2035 for local use and export, facilitating green fertilizer production2.

In Africa, the agricultural sector is crucial for the continent’s economies. For example, in sub-Saharan Africa, agriculture accounts for 14% of the region’s GDP3. The whole continent certainly has big agricultural potential, with 60% of the world’s uncultivated arable land4. Fertilizers are essential for food security in Africa, which has been further weakened in recent years by the impacts of Covid-19 and climate change.

Stamicarbon has completed a feasibility study to produce green ammonia in Angola. Read more about this project.

The costs of fertilizer imports, distribution and logistics are high, which reduces the availability of fertilizers for farmers. High port entry and domestic distribution costs, which increase even further in case of supply chain disruptions, make fertilizers difficult for farmers to afford.

Local fertilizer production would have a positive impact on the affordability and availability of fertilizers for farmers. Local communities would benefit from developmental projects undertaken as part of the corporate social responsibility of the fertilizer plants. This would create employment and educational opportunities and boost the development of infrastructure.

What is the configuration of the green fertilizer plant?

Combining green hydrogen with nitrogen from a nitrogen generation unit can produce ammonia without using fossil feedstocks or fuel. This ammonia would serve as the basis for further downstream fertilizer products. A typical green ammonia plant configuration comprises the following five sections:

- Solar/ Wind/ Hydro/Geothermal production plant for Renewable Energy generation

- Air Separation Unit for capturing atmospheric Nitrogen as a raw material to produce green ammonia

- Green Hydrogen plant consisting of Electrolysis, a process that separates water into hydrogen and oxygen using electricity generated from renewable resources

- Ammonia synthesis unit consisting of synthesis converter where hydrogen and nitrogen gases react to form ammonia over the catalyst at high pressure

- Nitrate fertilizer unit consisting of a nitric acid unit, ammonium nitrate, and other derivatives including calcium ammonium nitrate

Reducing the carbon footprint with green ammonia

For a long time, the fertilizer industry has used the economies of scale benefits, building bigger, higher-capacity production facilities. Today’s industry landscape, however, paints an alternative path forward: as the world transitions toward a zero-carbon economy, large-scale green projects cannot be rapidly implemented. That is because of limitations in renewable resource availability and the constraints on the production capacity of the electrolyzer. As a result, achieving economy of scale is a challenge when it comes to green fertilizer production.

Furthermore, with the intermittent supply of renewables and high prices of energy and hydrogen storage, there are still challenges to be overcome before large-scale green ammonia production is realized efficiently and economically. The good news is that at small and mid-size scales, there are projects active today overcoming these economic hurdles.

Reducing the environmental impact of fertilizers will continue to be an important topic as the world moves towards a more sustainable future. Existing environmental commitments and legislation are there to facilitate the energy transition. Ammonia is an essential building block for nitrates, and its demand will continue to grow with the growth of the world population that relies on fertilizers for food security. By using renewable energy for ammonia synthesis, the industry moves closer to a sustainable, carbon-free future of fertilizers.

More about Stamicarbon Ammonia Technologies:

- In a podcast, we discussed sustainable fertilizer production using NX Stami™ Ammonia technology. Listen

- Check out our green ammonia projects in: USA Middle East Kenya Angola

Resources:

1. Stefano Menegat, Alicia Ledo and Reyes Tirado. (2022). “Greenhouse gas emissions from global production and use of nitrogen synthetic fertilizers in agriculture.” Available at: https://www.nature.com/articles/s41598-022-18773-w

2. European Investment Bank (December 21, 2022), “New study confirms €1 trillion Africa’s extraordinary green hydrogen potential.” Available at: https://www.eib.org/en/press/all/2022-574-new-study-confirms-eur-1-trillion-africa-s-extraordinary-green-hydrogen-potential

3. Oxford Business Group (April 2021), “Agriculture in Africa 2021”. Available at: https://oxfordbusinessgroup.com/wp-content/uploads/files/blog/specialreports/960469/OCP_Agriculture_Africa_Report_2021.pdf

4. Wim Plaizier (January 22, 2016), “2 truths about Africa’s agriculture,” World Economic Forum. Available at: https://www.weforum.org/agenda/2016/01/how-africa-can-feed-the-world/

FAQ

- For more information, listen to our podcast about green ammonia and its applications in fertilizer industry.

What is green ammonia?

Green ammonia is ammonia produced by renewable energy resources, such as solar, wind, or hydro energy. Unlike traditional ammonia production that relies on fossil fuels and releases significant carbon emissions, green ammonia is a sustainable alternative, with least environmental impact.

What is the difference between green ammonia, blue ammonia, and gray ammonia?

The difference lies in how they are produced and their carbon footprint.

• Gray ammonia is made using fossil fuels, releasing CO2 into the atmosphere (if the CO2 is not used for urea production).

• Blue ammonia also uses fossil fuels, but the CO2 emissions are captured and stored (carbon capture and storage or CCS) to reduce their impact.

• Green ammonia is made using renewable energy; therefore, it is the most environmentally friendly option.

How is green ammonia produced?

The typical process involves using renewable energy to power the electrolysis of water, splitting it into hydrogen and oxygen. The hydrogen is then combined with nitrogen from the air via the Haber-Bosch process, powered by renewable energy, to produce ammonia. This removes the carbon emissions associated with traditional methods (using fossil fuels).

New technologies, like optimized high-pressure synthesis loops, can improve the efficiency of this process. Stamicarbon provides solutions that optimizes your ammonia plant’s efficiency and reduces its environmental footprint. Read more about our advanced technologies.

What technologies are used to produce green ammonia?

Key technologies are being used include:

• Water Electrolyzers: Water is split into hydrogen and oxygen by using electrolyzers; such as alkaline, PEM, and solid oxide electrolyzers.

• Air Separation Units (ASUs): Used to separate atmospheric air into its primary components. In this process, to obtain nitrogen from the air.

• Haber-Bosch Process: The established method for synthesizing ammonia from hydrogen and nitrogen.

However, new research is focused on more efficient and direct paths, such as direct ammonia electrolysis.

What are the applications of green ammonia?

Green ammonia has a wide range of applications:

• Fertilizer: As a direct replacement for traditional ammonia-based fertilizers, green ammonia plays a crucial role in sustainable agriculture. It enables the production of low-carbon or carbon-free fertilizers, reducing the environmental impact of food production and promoting more sustainable farming practices. This is a key focus for Stamicarbon, contributing to more sustainable agricultural practices.

• Fuel: Green ammonia is a promising alternative fuel for various sectors:

• Power Generation: It can be used directly in power plants or in fuel cells to generate electricity with minimal emissions.

• Shipping: As a maritime fuel, green ammonia offers a pathway to decarbonize the shipping industry, reducing its reliance on fossil fuels.

• Aviation: While still in the early stages of development, green ammonia is being explored as a potential sustainable aviation fuel (SAF).

• Energy Storage: Green ammonia can be stored for extended periods, and then transported to locations where it is needed, providing a flexible and dispatchable source of energy.

• Industrial Feedstock: Green ammonia can be used as a renewable feedstock, replacing fossil fuel-derived chemicals in the production of plastics, textiles, and other materials.

How much does it cost to produce green ammonia?

It depends on the cost of renewable electricity, electrolyzer efficiency, and plant size. However, we can say that the cost of green ammonia production is decreasing as renewable energy becomes cheaper and electrolyzer technology improves.

Do you need a cost estimation for your plant? Contact our experts.

How much does it cost to build a green ammonia production unit?

Construction costs vary greatly depending on the scale of the facility, the chosen technologies, and location-specific factors. A small-scale pilot plant might cost a few million dollars, while a large-scale commercial plant can cost hundreds of millions or even billions. Stamicarbon specializes in providing modular and scalable solutions to optimize costs for clients. Get in touch with our experts and explore tailored solutions for your plant.

Is it possible to produce green ammonia on a small scale?

Yes, absolutely! Stamicarbon’s High-pressure Ammonia technology is specifically designed for small to medium-scale production. This technology uses renewable energy resources such as solar, wind, or hydropower to produce ammonia sustainably.

Read more about our successful project in USA, Angola and Kenya .

What are the advantages of NX Stami™ Ammonia technology?

• High CAPEX efficiency

• Strongest reference base with four small-scale plants in operation

• Lean, compact and modularized design

• High plant reliability thanks to a multi-service reciprocating compressor

• Compliance with the highest environmental standards

• Integrated with water electrolyzers and Stamicarbon’s nitric acid and urea technologies

How can I implement Stamicarbon's ammonia technology in my plant?

Contact us to discuss your specific needs and learn more about how Stamicarbon can help you achieve your green ammonia production goals. We offer a range of services, from feasibility studies to complete plant design.