Local for local - Assessing the feasibility of green ammonia production in Angola

By Anna Bashuk, Content Marketeer at Stamicarbon

Photos provided by Lindsay Reed, CEO at Minbos Resources

Stamicarbon has recently completed a study for Minbos Resources to determine the technical feasibility of the Capanda green ammonia project in Malanje province, Angola, east of the capital Luanda. This pre-feasibility study defined the required process units, plant configuration and estimated CAPEX and OPEX for a 320 MTPD plant producing green ammonia as feedstock for 50% Calcium Ammonium Nitrate (CAN) and 50% Low-Density Ammonium Nitrate (LDAN). CAN will be used as fertilizer for the local market, while LDAN will be exported to the mining sector in neighboring regions. The facility aims to be fully designed as carbon-free by avoiding using natural gas or other carbon-based feedstocks.

Stamicarbon has interviewed Lindsay Reed, Chief Executive Officer at Minbos Resources, for more insights into the project.

Angola’s potential for local fertilizer production

Mr. Reed sees Angola as a growing fertilizer market with a large potential for agricultural development, with millions of hectares of uncultivated arable land. “Angola has energy, it has water, it has land, and its population is young,” he said. “43% of its population is under 15 and 2% of its population is over 65. It will probably be the fastest-growing population on the planet between now and 2050. And they have the infrastructure and the institutions being built from proceeds from the energy, oil and gas sector which they could now re-deploy into the agriculture sector.” Furthermore, the existing mining explosive market in the African Western Copper Belt is also projected to grow rapidly.

Minbos started the Cabinda phosphate fertilizer project in Angola before working on the green ammonia study. It felt like a natural step to work on a nitrogen-based fertilizer next. During his travels to the country, Mr. Reed discovered that the price of electricity in Angola was so low that landlords did not charge their tenants for power. This gave the idea to leverage this low-cost, available electricity in a green ammonia project.

According to Mr. Reed, three unique characteristics make the Capanda green ammonia project feasible and attractive for the market:

- Low-cost electricity

- High-quality water

- African Inland Premium

Let’s look at each in more detail.

Low-cost electricity

Electricity price largely drives the OPEX costs, which is why low-cost electricity is important for reducing the reliance on natural gas for ammonia production. Using hydroelectric power from a nearby source allows to have constant electricity supply, which can be supplemented with other renewable energy resources to compensate for intermittency. The green ammonia plant will rely on up to 200 MW of 100% renewable electricity from the nearby Capanda Hydroelectric Dam available at one of the most competitive tariffs.

“The hydroelectric power is already there – we can build two kilometers away from a substation – the dam is already there. We don’t have to build solar panels; we don’t have to build wind farms – it’s already there, ready to plug into. That’s the first big advantage, along with the price,” Mr. Reed said.

High-quality water

Hydrogen necessary for green ammonia production is obtained using water electrolysis. Water used in this process has to be of high quality to prevent damage to the electrolyzer. High-quality water, which is already available for the Capanda project, makes a big difference in electrolysis, minimizing the CAPEX and OPEX associated with treating saline groundwater or seawater.

African Inland Premium

Stamicarbon, together with the International Fertilizer Development Center, calculated that the financial advantage defined as African Inland Premium could be as high as USD 200 per ton of product. Firstly, Capanda fertilizers will not incur the costs of marine freight, insurance, customs and port fees, product packaging and 300 km of land transport, compared to the competing fertilizer products from North and West African countries. Secondly, Capanda explosives will have a land transport advantage of 1000 km and additional marine freight and port cost advantages over competing products from South Africa. “That’s a massive advantage, which means the competing products are USD 200/t behind you by the time they drove past your gate to get to your market,” Mr. Reed said.

However, African Inland Premium does not only capture the financial advantage of producing green ammonia in Angola but also the added value of producing fertilizers locally for local consumption. “It’s a social advantage in the sense that you are making something locally to use it locally. Rather than importing something and making money for another country, you are taking more of the value chain inside the country. So, there is a social advantage and a financial advantage,” Mr. Reed said.

A case for distributed ammonia production

Scaling down ammonia plants for distributed production allows to match the demand of the local market and the input of renewable electricity from small- and medium-scale hydro, wind and solar installations. “I think Stamicarbon understands where green ammonia sits in the world, where it can work, and where it cannot,” Mr. Reed said. “You need to use hydrogen where you make it. The cost of transportation for hydrogen is prohibitive, the energy density is not favorable, and the temperature, the cost of getting it so low, and the losses because it’s such a small molecule – all of these things lead to say you have to use hydrogen where you make it. And Stami understands that, and slowly the world is getting there I think. The best place to start is where there is already a market. If you are going to create a new technology and a new value chain and then create a new market, that makes it hard. If you can do the first two steps and slot into an existing market, then that’s a lot easier.”

Next steps for the Capanda project

As the next step in the project, Minbos is currently securing a plot of land to build the green ammonia plant, which is proposed to be located within 15 km of the Capanda Hydroelectric Dam. Furthermore, the company is about to enter an MOU with an industry partner to do further studies, including a dry season flora and fauna survey, and investigate the generator and substation capacity of RNT, the network operator in Angola. “We won’t get bigger – we might get smaller. We might change or look to supplement with some wind and solar. We’ll have these conversations now and take that forward to the feasibility study,” Mr. Reed said.

Read more about the findings of the technical study in full detail, and NX Stami™ Ammonia technology.

FAQ

- For more information, listen to our podcast about green ammonia and its applications in fertilizer industry.

What is green ammonia?

Green ammonia is ammonia produced by renewable energy resources, such as solar, wind, or hydro energy. Unlike traditional ammonia production that relies on fossil fuels and releases significant carbon emissions, green ammonia is a sustainable alternative, with least environmental impact.

What is the difference between green ammonia, blue ammonia, and gray ammonia?

The difference lies in how they are produced and their carbon footprint.

• Gray ammonia is made using fossil fuels, releasing CO2 into the atmosphere (if the CO2 is not used for urea production).

• Blue ammonia also uses fossil fuels, but the CO2 emissions are captured and stored (carbon capture and storage or CCS) to reduce their impact.

• Green ammonia is made using renewable energy; therefore, it is the most environmentally friendly option.

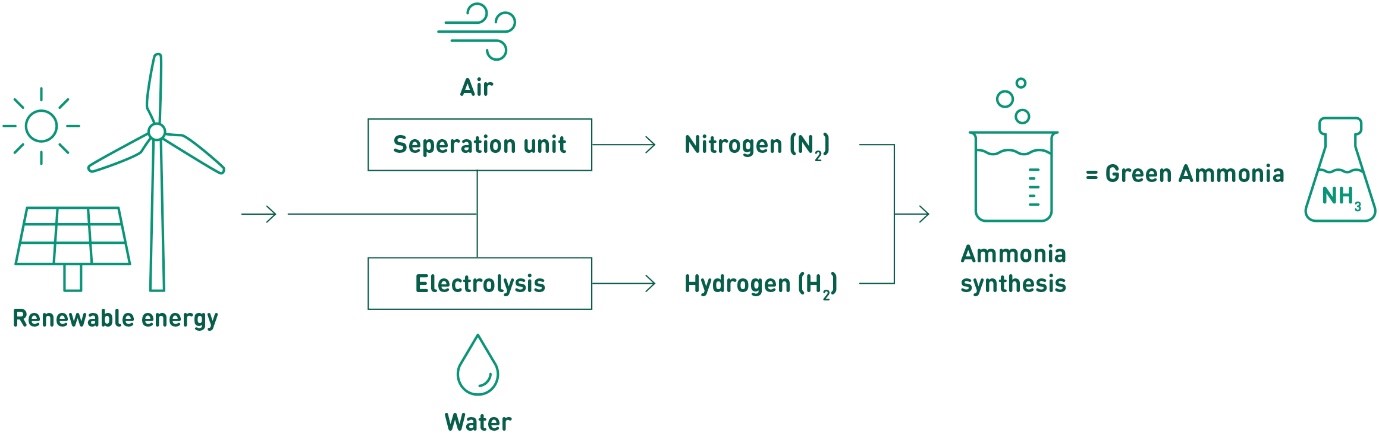

How is green ammonia produced?

The typical process involves using renewable energy to power the electrolysis of water, splitting it into hydrogen and oxygen. The hydrogen is then combined with nitrogen from the air via the Haber-Bosch process, powered by renewable energy, to produce ammonia. This removes the carbon emissions associated with traditional methods (using fossil fuels).

New technologies, like optimized high-pressure synthesis loops, can improve the efficiency of this process. Stamicarbon provides solutions that optimizes your ammonia plant’s efficiency and reduces its environmental footprint. Read more about our advanced technologies.

What technologies are used to produce green ammonia?

Key technologies are being used include:

• Water Electrolyzers: Water is split into hydrogen and oxygen by using electrolyzers; such as alkaline, PEM, and solid oxide electrolyzers.

• Air Separation Units (ASUs): Used to separate atmospheric air into its primary components. In this process, to obtain nitrogen from the air.

• Haber-Bosch Process: The established method for synthesizing ammonia from hydrogen and nitrogen.

However, new research is focused on more efficient and direct paths, such as direct ammonia electrolysis.

What are the applications of green ammonia?

Green ammonia has a wide range of applications:

• Fertilizer: As a direct replacement for traditional ammonia-based fertilizers, green ammonia plays a crucial role in sustainable agriculture. It enables the production of low-carbon or carbon-free fertilizers, reducing the environmental impact of food production and promoting more sustainable farming practices. This is a key focus for Stamicarbon, contributing to more sustainable agricultural practices.

• Fuel: Green ammonia is a promising alternative fuel for various sectors:

• Power Generation: It can be used directly in power plants or in fuel cells to generate electricity with minimal emissions.

• Shipping: As a maritime fuel, green ammonia offers a pathway to decarbonize the shipping industry, reducing its reliance on fossil fuels.

• Aviation: While still in the early stages of development, green ammonia is being explored as a potential sustainable aviation fuel (SAF).

• Energy Storage: Green ammonia can be stored for extended periods, and then transported to locations where it is needed, providing a flexible and dispatchable source of energy.

• Industrial Feedstock: Green ammonia can be used as a renewable feedstock, replacing fossil fuel-derived chemicals in the production of plastics, textiles, and other materials.

How much does it cost to build a green ammonia production unit?

Construction costs vary greatly depending on the scale of the facility, the chosen technologies, and location-specific factors. A small-scale pilot plant might cost a few million dollars, while a large-scale commercial plant can cost hundreds of millions or even billions. Stamicarbon specializes in providing modular and scalable solutions to optimize costs for clients. Get in touch with our experts and explore tailored solutions for your plant.

How much does it cost to produce green ammonia?

It depends on the cost of renewable electricity, electrolyzer efficiency, and plant size. However, we can say that the cost of green ammonia production is decreasing as renewable energy becomes cheaper and electrolyzer technology improves.

Do you need a cost estimation for your plant? Contact our experts.

Is it possible to produce green ammonia on a small scale?

Yes, absolutely! Stamicarbon’s High-pressure Ammonia technology is specifically designed for small to medium-scale production. This technology uses renewable energy resources such as solar, wind, or hydropower to produce ammonia sustainably.

Read more about our successful project in USA, Angola and Kenya .

What are the advantages of NX Stami™ Ammonia technology?

• High CAPEX efficiency

• Strongest reference base with four small-scale plants in operation

• Lean, compact and modularized design

• High plant reliability thanks to a multi-service reciprocating compressor

• Compliance with the highest environmental standards

• Integrated with water electrolyzers and Stamicarbon’s nitric acid and urea technologies

How can I implement Stamicarbon's ammonia technology in my plant?

Contact us to discuss your specific needs and learn more about how Stamicarbon can help you achieve your green ammonia production goals. We offer a range of services, from feasibility studies to complete plant design.