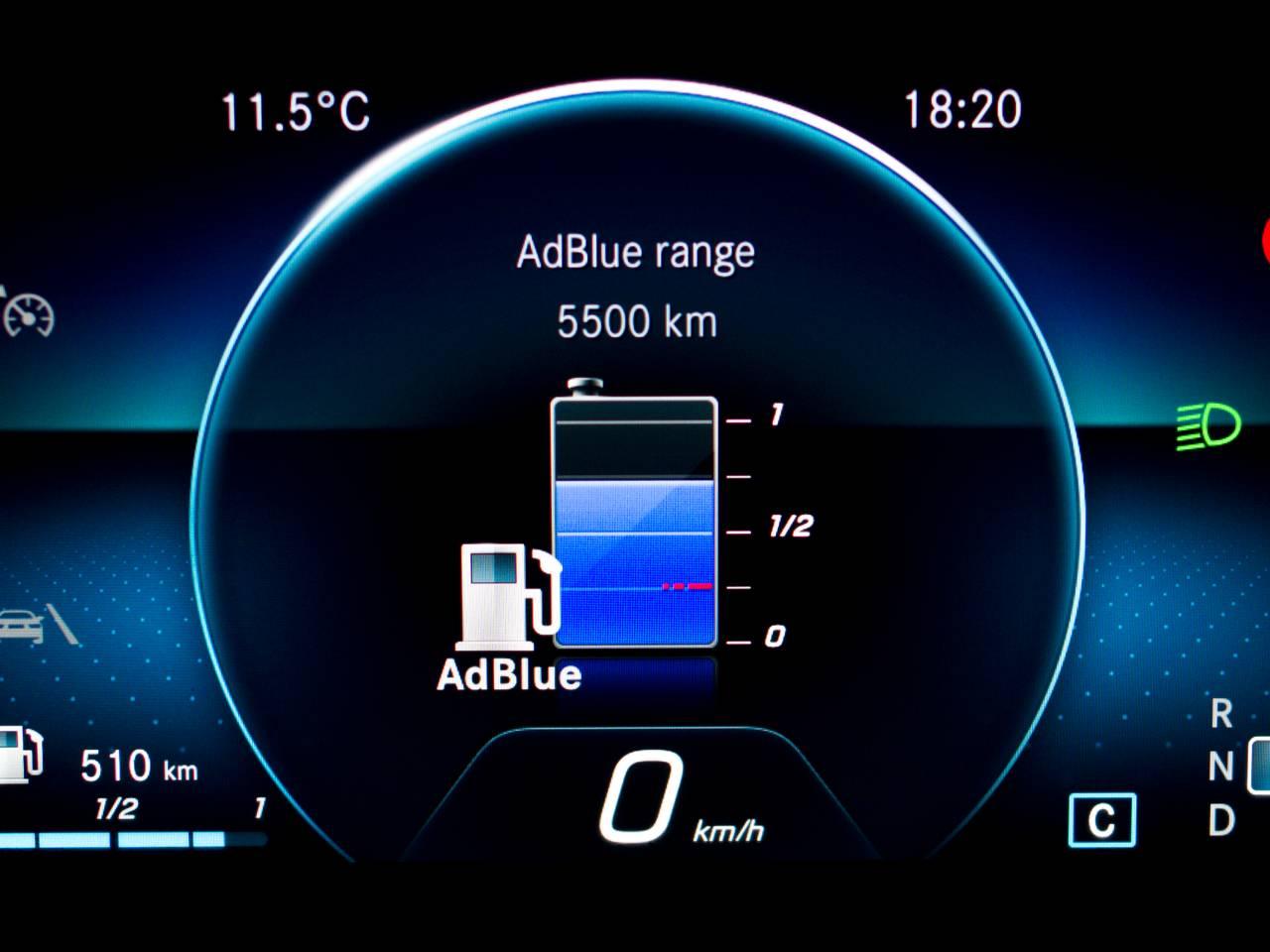

NX Stami™ Specialties are innovative, future-proof products and services that contribute to reducing nutrient loss, improving yields, reducing NOx emissions from diesel engines, enabling the production of liquid UAN and granular UAS, and limiting environmental impact.