Bring your plant’s steam consumption to an unprecedentedly low level

The Challenge

Environmental concerns and the limited availability of energy resources make it necessary to reduce the energy consumption of urea plants. Especially in areas with high energy prices, reducing steam consumption of the plant can bring significant advantages. Now that’s easier said than done, you may think. But Stamicarbon has a solution.

The Solution

The Ultra-Low Energy (ULE) Design, part of our LAUNCH MELT™ series, makes urea plants much more energy-efficient without compromising on the reliability of operation.

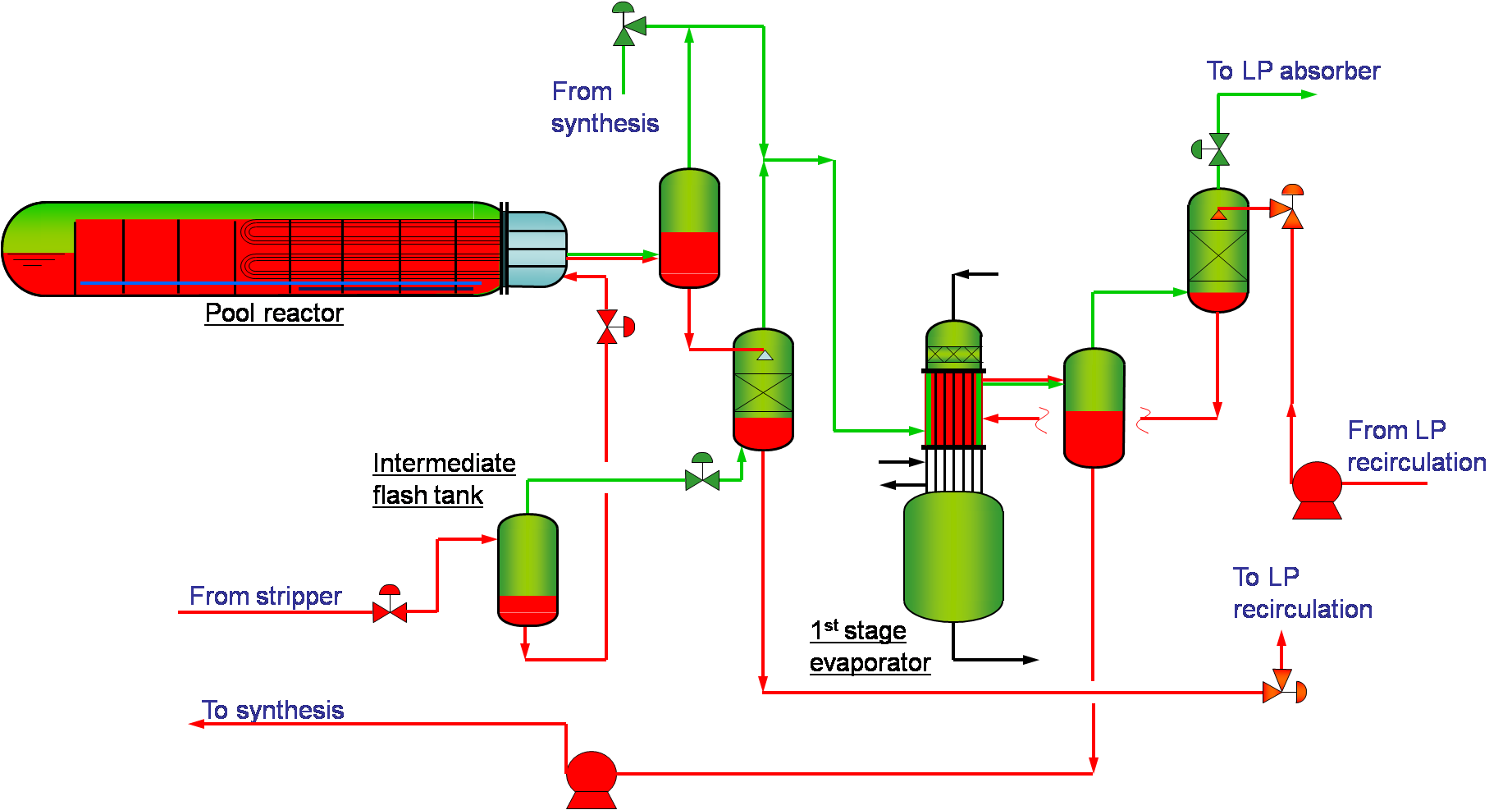

This technology allows for heat supplied in the form of high-pressure steam to the urea plant to be used three times instead of two (so-called N=3 heat integration concept). As a result, it reduces steam consumption by about 35% and cooling water consumption by about 16%, compared to traditional CO2 stripping processes

The centerpiece of this technology is the Ultra-Low Energy pool reactor with two heat exchanging tube bundles, utilizing proprietary Stamicarbon E-type material.

Process diagram of the Ultra-Low Energy Design

The ULE Design was launched in 2012 and today has been contracted for six grassroot urea plants:

- Jinjiang Xinlianxin and Hubei Sanning plants in China (2334 MTPD each) in operation since 2021

- Gemlik Gübre plant in Turkey (1640 MTPD granulated urea and 500 MTPD UAN) and Henan Xinlianxin plant in China (2334 MTPD) under construction

- Two other plants in China in the design phase (2334 MTPD each)

Advantages of the ULE Design

The energy consumption of the Ultra-Low Energy plant is considered to be a benchmark performance worldwide. This technology substantially lowers operating expenses (OPEX) and offers significant environmental benefits by reducing energy consumption. The synthesis section includes only two pieces of high-pressure equipment: a high-pressure stripper and a high-pressure pool reactor, optimizing the CAPEX of the plant typically up to 3000 MTPD. For larger plant capacities, also a vertical reactor would be included in the synthesis.

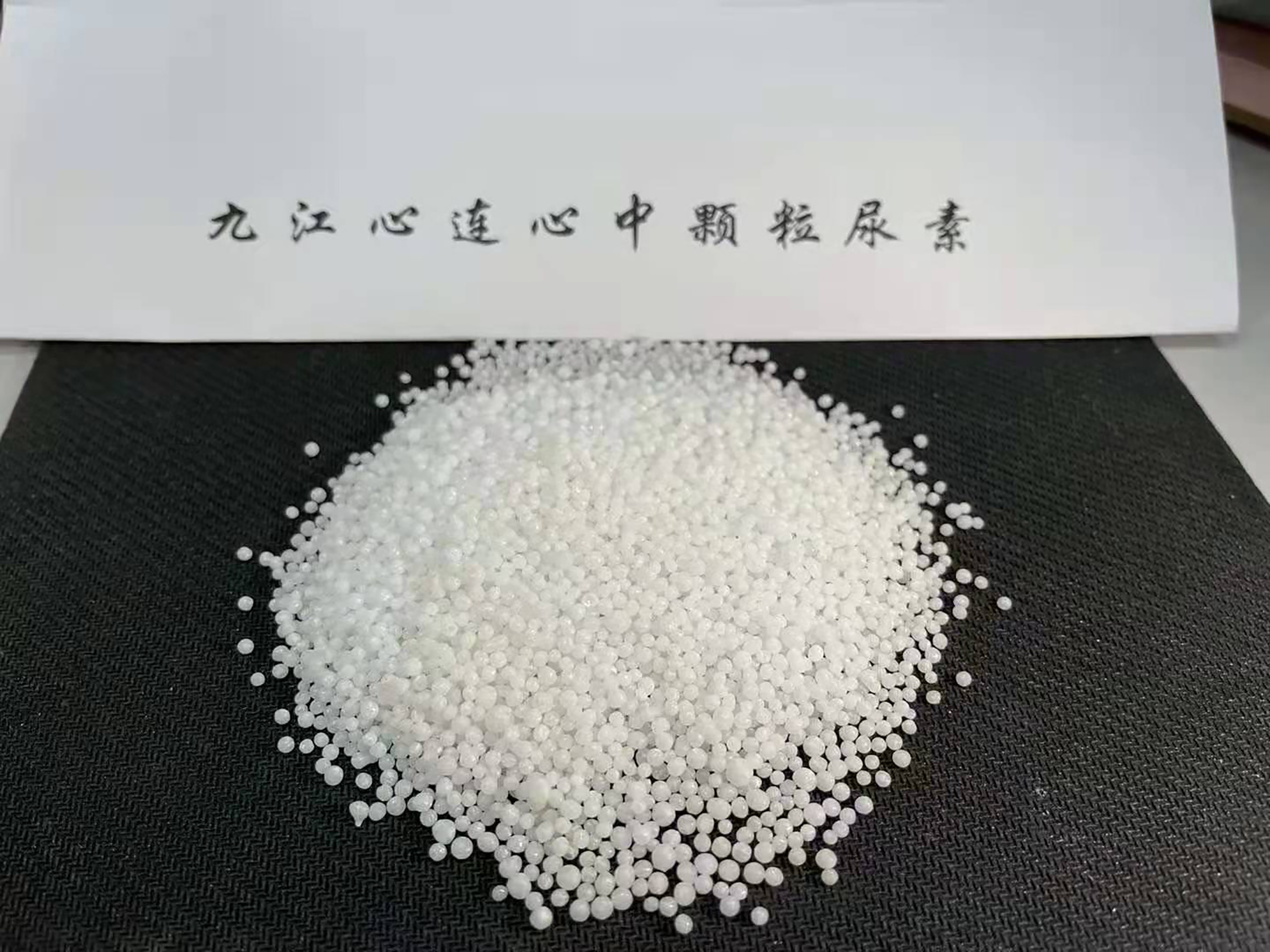

First urea plant based on the ULE Design

Ultra-Low Energy Design Advantages

By choosing the Ultra-Low Energy Design, you receive the following advantages:

- Lowest steam consumption

- Lowest cooling water consumption

- Minimal maintenance due to E-type materials

- Easy and reliable operation

- Lower investment costs in the urea section

- Lower operating costs (OPEX)

First Start-up Experience

The ULE plant of Jinjiang Xinlianxin (2334 MTPD) in China successfully started up in February 2021. The plant was initially operated with turndown capacity operation, which was increased to above 100% within the first week after ensuring feedstocks.

At an average plant operation capacity of 102%, the performance parameters demonstrate the lowest high-pressure steam consumption (23 bara, 330°C) that could be expected based on the design variation. The steam consumption is reduced by about 35% and cooling water consumption is reduced by about 16% compared to Stamicarbon’s Pool Condenser and Pool Reactor Designs.

Urea produced at the first Ultra-Low Energy plant

ULE Design for Non-Stamicarbon Plants

A pool condenser or pool reactor based on the ULE concept can replace the existing aging equipment, increasing plant capacity while simultaneously reducing energy consumption.

ULE is also a powerful addition to the available revamp solutions. Every design has to be tailored to the specific objectives of the revamp project but can bring characteristic performance improvements and advantages.