Meet the most stringent environmental regulations

The Challenge

The off-gas from urea granulation contains urea dust and ammonia, so it must be cleaned before being released into the atmosphere.

Although conventional scrubbing technologies easily collect larger particles, they fail to capture a high degree of submicron dust. As environmental regulations for fine particulate emissions become increasingly stringent, there is a growing need for more effective scrubbing technologies.

The Solution

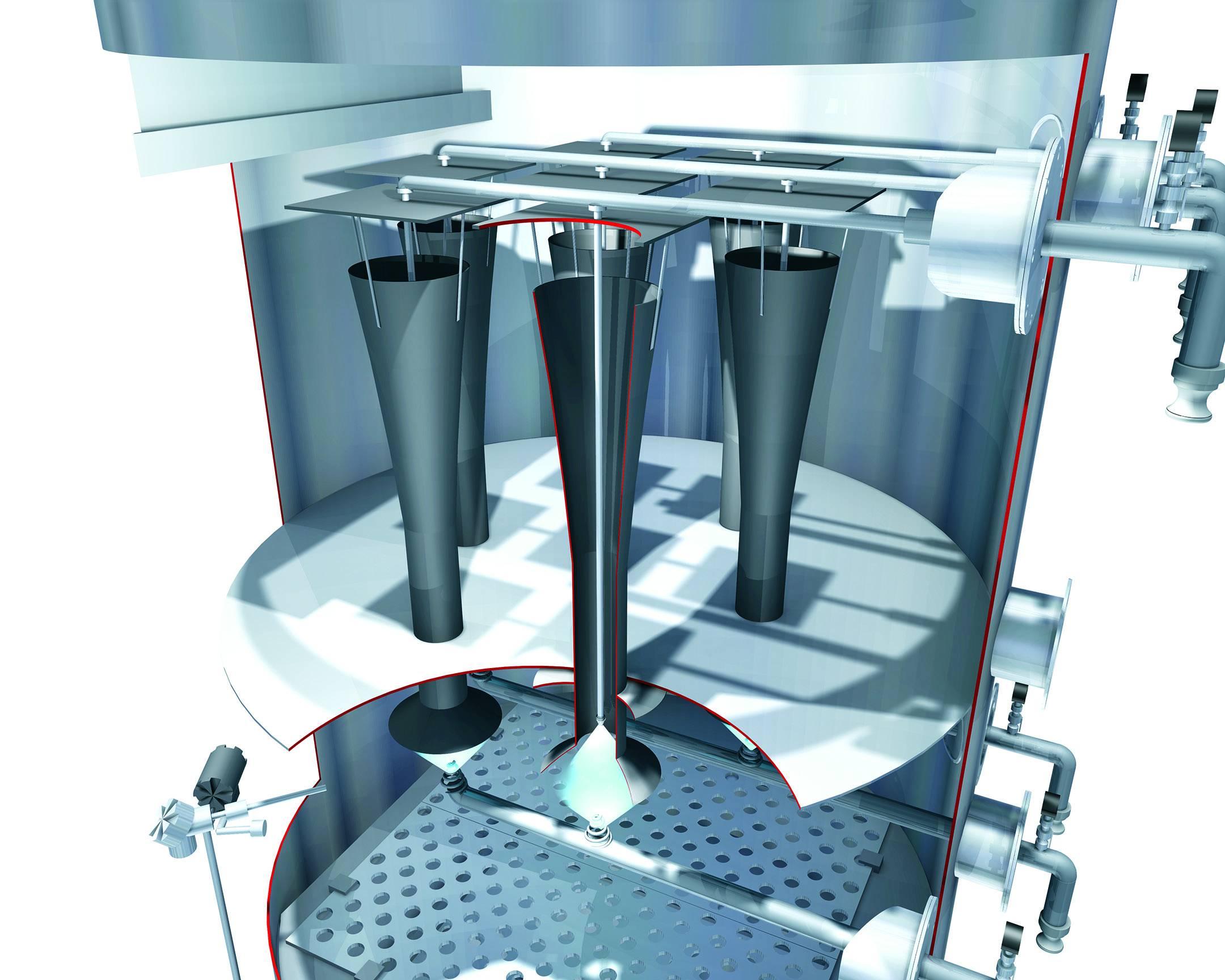

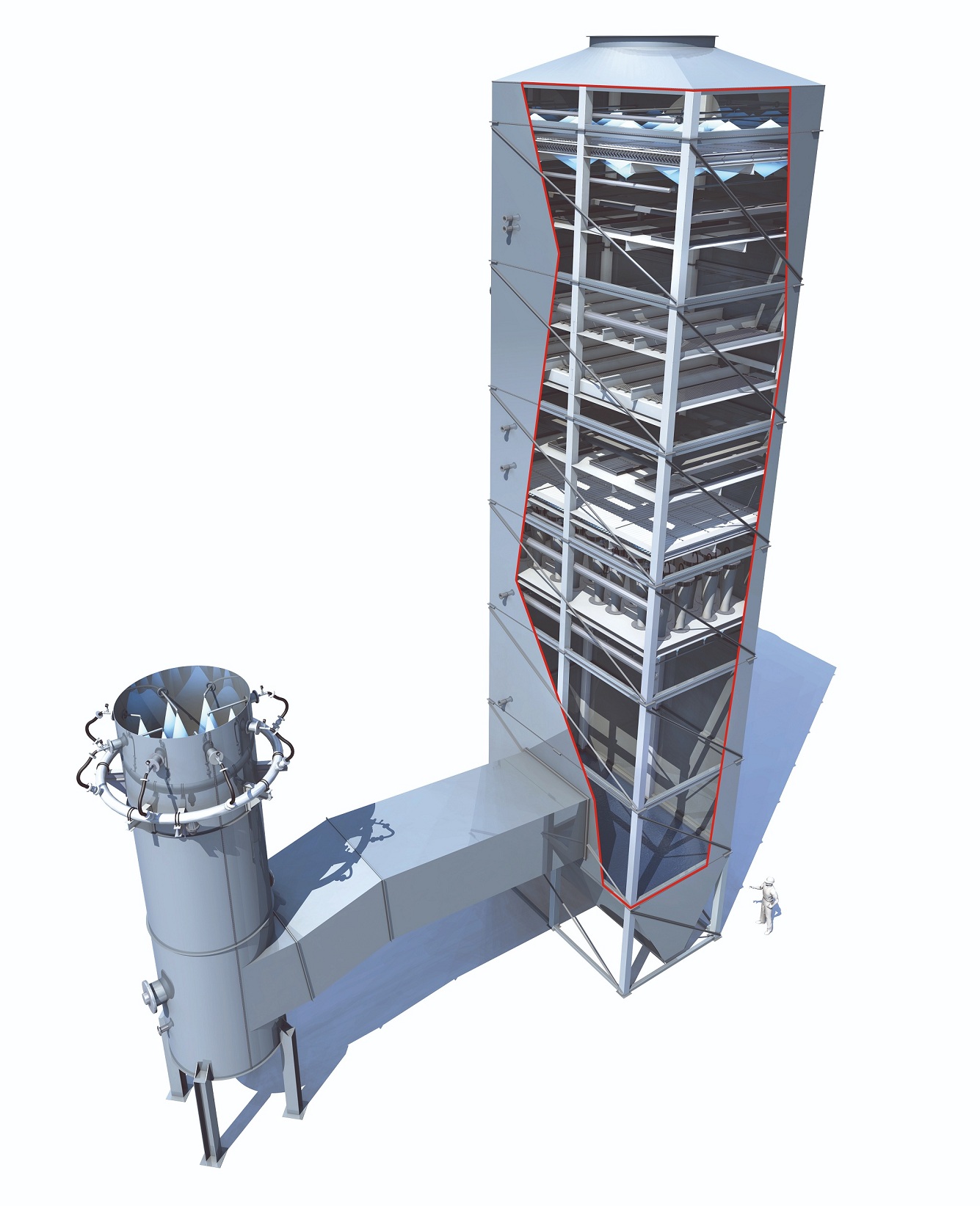

Stamicarbon and EnviroCare International have co-developed the MicroMist Venturi™ (MMV) Scrubber for granulation plants and the Jet Venturi Scrubber for prilling towers. These innovative, high-performance technologies remove submicron filterable particulate, condensable particulate, and soluble gases at very high efficiencies with low energy input.

By using the MMV Scrubber, you can achieve urea dust emissions below 10 mg/Nm3. At the same time, the integration of a polishing Wet ElectroStatic Precipitator (WESP) can bring emission levels even lower to 5 mg/Nm3 as already successfully demonstrated in two Stamicarbon urea plants.

The MMV Scrubber has been paired with Stamicarbon’s urea fluid-bed granulation technology, setting a new standard in urea granulation and emission control.

Why MMV Scrubber

The process of urea melt crystallization generates urea dust and releases some ammonia present in the urea melt, after which both components are emitted into the air.

The MMV vessel collects urea dust, including submicron particles, while the urea scrubbing solution is recycled back into the melt plant. Ammonia is captured with the application of acidic scrubbing with sulfuric or nitric acid, which reacts with ammonia, reducing its concentration in the exhaust air.

MMV Scrubber for Volgafert during installation

By choosing the MMV Scrubber, you receive the following advantages:

- High-efficiency submicron particulate collection

- Easy installation due to modular design

- Best available turndown ratio

- Can handle fluctuations in gas volume to be treated

- High-quality, low-maintenance components

- Proven track record

- Flexibility in use by removing or adding venturi tubes if needed

Initial real-world experiences with MMV Venturi Scrubbers have demonstrated that this emission technology enables plant owners to exceed the requirements of the most stringent environmental regulations, ensuring sustainable plant operation in the coming decades.