Urea plant simulator implemented with cloud solution

Urea plants designed with Stamicarbon’s Ultra Low Energy Design (for lowest energy consumption) comes with a built-in urea simulator. This allows Stamicarbon to gain a deeper understanding of plant process dynamics, which in turn leads to process improvements, knowledge feedback and improved start-up training for operators.

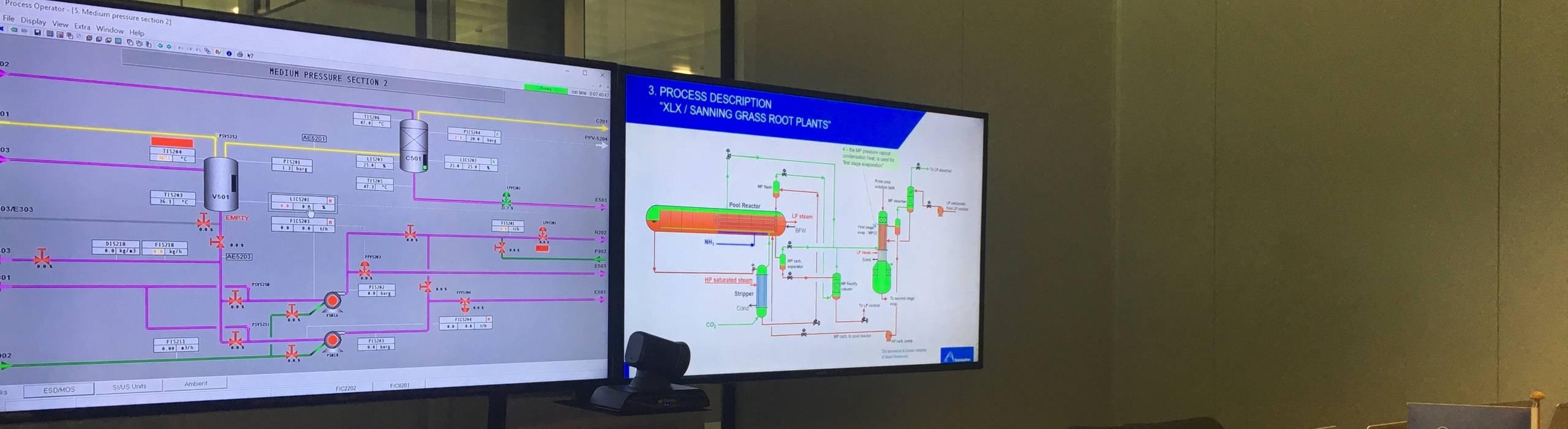

Now Stamicarbon has taken another step forward by developing a urea plant simulator with cloud solution (made with Protomation technology), enabling operator training to be performed remotely.

“This is really exciting. We can now give operators hands-on training and help them to be well prepared, without physically being there,” said Rahul Patil, Senior Process Engineer at Stamicarbon. “Especially in the current situation, with continuing travel restrictions, we are pleased to be able to support our clients remotely.”

Stamicarbon client, Sanning (in Hubei, China), will be the first client to receive operator training remotely. It will be an intensive five day training (starting today, September 28th, 2020) with multiple operator trainees simulating the plant operation simultaneously.

Stamicarbon Product Portfolio Manager, Joey Dobrée said: “It’s important to invest in new IT developments to help solve the challenges we are currently facing, such as tools that enable companies to support their clients from a distance.”