Achieve higher plant safety and availability with well-trained personnel

The Challenge

Managing a plant is challenging. An operator must ensure optimal conditions to achieve good performance, including the plant's safety, stability and profitability.

Effective training of plant operators on start-up and shutdown procedures, emergency shutdowns, day-to-day operations and various scenarios in the plant is the key to improving operator knowledge, plant safety and reliability. But on-site training has its limitations since many scenarios would mean the trainee has to actually control the plant and even require shutting it down.

How to better understand dynamic plant behavior and safely and effectively prepare operators for emergencies?

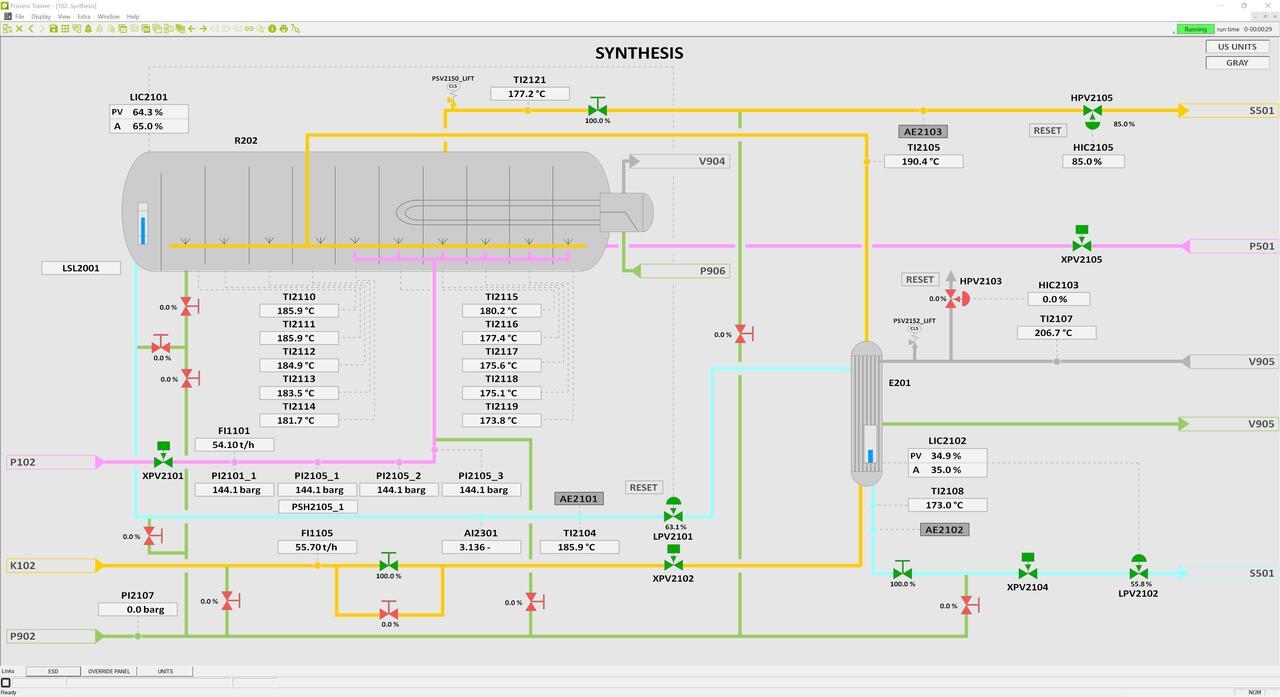

The Solution: Technology Training Simulator

High-fidelity Technology Training Simulator (TTS), developed by NX Stami™ Digital, accurately simulate the dynamic behavior of the plant (accuracy >98%). The TTS allows operators to run unlimited training scenarios with the look and feel of a real distributed control system (DCS).

A TTS enables you to:

- Educate operators well

- Provide insights into processes

- Practice every situation

- Structure training as you want

- Practice awareness management

- Have detailed reports available

- Facilitate your instructor and/or trainer

- Have full graphical information

- Run tests, tune controllers and predict or investigate situations to know plant behavior better

The investment typically pays back in under a year and sometimes even sooner. Considering that downtime in a high-capacity plant due to an emergency shutdown could cost over EUR 500K of lost production per day, the ROI in such a situation would be only a few days.

Equipped with an instructor station and several trainee stations, the TTS allows for individual and group training, where trainees can operate a simulated version of the process with or without training scripts and scoring.

The TTS realistically simulates scenarios, allowing to observe, test and train operator response in various scenarios, including plant startup and shutdown, plant upsets, malfunctions and failures.

Customized Training

Customer-specific TTS systems are joint efforts between Stamicarbon and its customers and can be tailored to customers’ requirements.

Licensing of these applications is subject to certain conditions and approval.

Stamicarbon builds and delivers TTS systems based on high-fidelity and robust dynamic process models. Stamicarbon’s Project Execution Plan (PEP) includes four phases: Definition, Planning, Execution and Evaluation.

TTS Project Execution Plan

- Phase 1: Definition

We set up the functional specification of the system to be designed and built in close cooperation with the customer and identify and document functional and non-functional requirements, extensively elaborating on use cases and exception handling.

- Phase 2: Planning

We set out the route to achieving the project objectives by considering constraints in various resources, resulting in a complete project plan.

- Phase 3: Execution

The system analyses and design result in evolutionary and iterative system implementation. Prototypes play a central role in communication with the intended users of the system. This approach is particularly valuable for the design of man-machine interfaces.

- Phase 4: Evaluation

The user’s perception of the process and the system’s internals is important for its optimal use, so the man-machine interface must be designed with great care and jointly developed together with the users.

TTS Advantages

Financial

- Fewer operational mistakes resulting in less downtime

- Fewer deviations from optimal conditions for more efficient performance

- Increased operating reliability

- Faster recovery from upsets

- Low life cycle cost

- Lower insurance costs

- Better financial results

- Compliance with applicable laws

Safety

- Increased safety

- Technical accuracy, high fidelity

- Risky/strange situations can be trained

- Deeper timing and process knowledge

- Aimed intervention at disturbances for faster operator response under deviations

Personnel

- Well-trained personnel

- More effective and efficient work

- Game-like training as a more interactive way of training

- More reliable and self-confident (new) operators

- Periodic training to familiarize operators with the system

- Learning from mistakes (learning by doing)

- Reduced training times

Engineers also benefit from the TTS by using it not only as a training tool but also as an engineering tool to run tests, improve plant operating procedures, tune controllers and predict or investigate situations to know the plant behavior better.

25 years of experience in process simulation

With more than 25 years of global experience in the field of production processes, process control and process simulation, NX Stami™ Digital is fully specialized in technology training simulator for a wide range of customers in different kinds of industries.

Licensors, engineering contractors, plant owners and training centers use our solutions.

In the past years, we have delivered solutions to a significant number of companies in the fertilizer and adjacent industries, as well as companies in other industries such as Nutrien, Petrobras, SKW Piesteritz, Sorfert, AkzoNobel (Nobian), Kinetics Technology, Petronas, SABIC, Saudi Aramco, and thyssenkrupp.

All our TTS systems and models are developed in-house. To ensure continuity, NX Stami™ Digital is fully committed to constantly improving and developing our specific knowledge. We implement cutting-edge technologies into our flagship TTS software to best serve our customers’ needs.

Each TTS project includes:

- A high-fidelity TTS

- Customer-specific applications

- Training scripts

- Specific custom process simulations

- Training on how to use the TTS

- Maintenance of the products and software

- On-site support

Learn More

In a podcast, Andreas Ackermann and Heiko Zweering from the SKW Piesteritz urea plant shared their experience using the Stamicarbon Technology Training Simulator.

Listen to Podcast

You can also watch the full video of this conversation on YouTube.

Watch on YouTube

Request a demo from our technical experts and learn more about our NX Stami™ Digital products.