Improve the quality of your urea prills in a safe and cost-effective way

The final quality of your urea is not decided when it leaves the prilling tower, but when it reaches the customer. Environmental factors and handling stress can quickly degrade even the best-made prills.

Addressing these post-production challenges is the final, essential step in delivering a premium product.

The challenge

Urea prills readily absorb moisture from the environment, leading to caking, decreased dynamic strength, and increased dust formation during product handling. Especially when storing prills in bulk for a long time, you may observe the reduced product quality, handling problems and potential health risks.

Typically, these challenges are addressed by either packaging urea prills in bags and/or adding urea formaldehyde to increase prill strength. This comes with a few disadvantages:

- Complicates loading and unloading the product

- Increases product cost

- Limits technical applications of the product

- Potential health risks due to formaldehyde handling

Our solution

Stamicarbon’s coating composition solution is applied as an additive coating to increase urea prills' quality and moisture resistance, helping maintain prill impact strength during handling and storage, reducing dust, and preventing caking and layering.

Advance Coat™ sprayed over the belt with a specific angle and spray pattern ensures good coverage over the belt

Low chemical content and water-soluble components make Advance Coat™ a sustainable product that exceeds the latest environmental standards and offers a high-quality solution, safe for people and the environment.

Advance Coat™ is a better and safer alternative to urea formaldehyde as an anti-caking agent, as it doesn’t pose health and environmental concerns, especially for clients who use urea in technical applications, such as DEF/AdBlue®, where formaldehyde is unacceptable.

By applying Advance Coat™, you can permanently stop the addition of urea formaldehyde in prilling applications, maintaining the quality of urea prills in a cost-effective, safe and crop-friendly way.

Advantages of Advance Coat™

When choosing Advance Coat™, you receive the following advantages:

- End-of-pipe solution that requires no significant modifications, reducing CAPEX

- Excellent product quality even after six months of storage

- Bulk storage and shipping of prills without the use of urea formaldehyde

- Keeps product specifications during shipping

- No foaming in technical applications, thanks to the unique coating formulation

- Safety to use treated prills as a cattle feed supplement

- Suitability for DEF/AdBlue® application (compatible with ISO specification)

- Lower logistic costs for product transportation

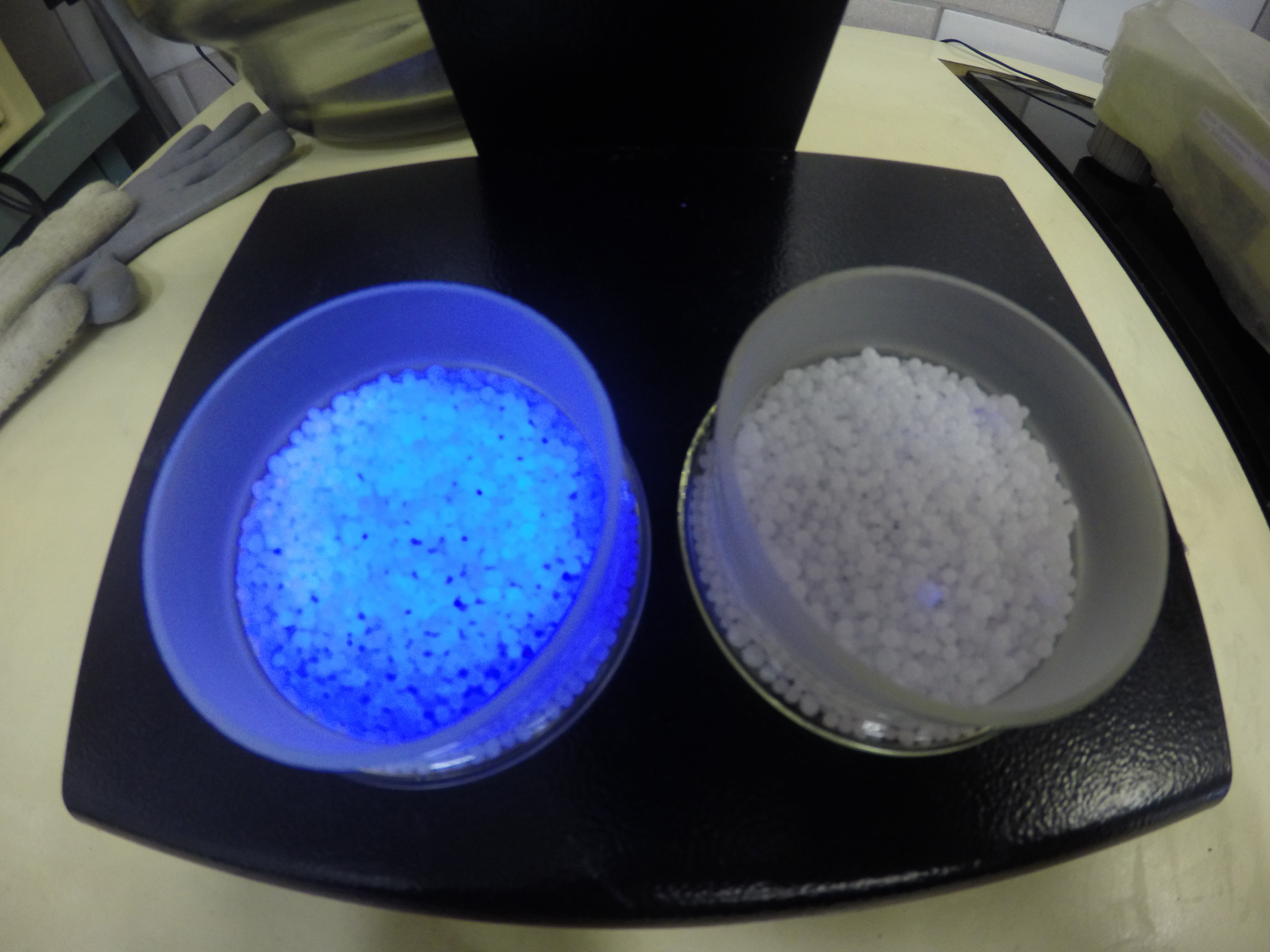

Under UV light coated prills light up blue (left), and uncoated do not (right)

Advance Coat™ testing

There’s no need to question whether Advance Coat™ is the right solution for you.

Stamicarbon can arrange a testing program in your plant so that you can see its performance first-hand in terms of caking, moisture absorption, dust formation during product handling, and other parameters.

Previous test results have shown that:

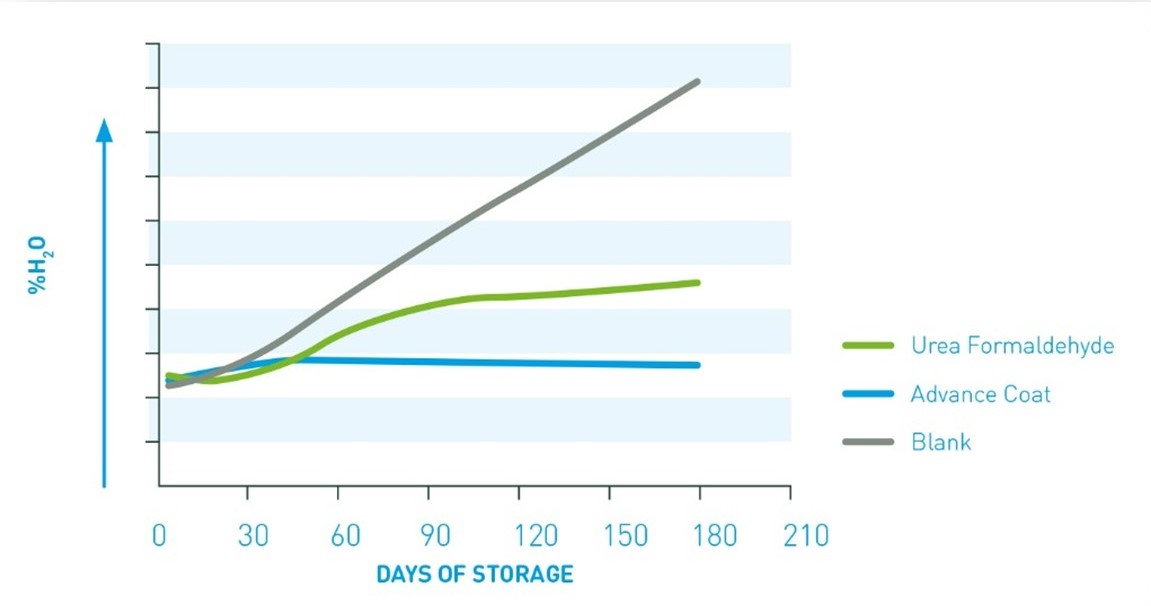

- Prills treated with Advance Coat™ absorb less moisture than both untreated prills and prills treated with urea formaldehyde.

- The dynamic strength of urea prills treated with Advance Coat™ hardly declines compared to both untreated prills and formaldehyde-treated prills.

- The dust content during the storage is significantly lower when using Advance Coat™.

- Advance Coat™ noticeably reduces the caking tendency of urea prills.

In the graph above you can see a comparison of the water content in the prill between UF and Advance Coat™ during the storage time.

Unlike the product with added UF, the product with added Advance Coat™ has stable water content during storage time, which will consequently limit the caking formation of the final product.

Case in point

For two years in a row, our client in China has been ordering a yearly supply of Advance Coat™ Urea Prill Strength, satisfied with the good anti-caking performance of Stamicarbon’s coating solution. “We are very satisfied with the anti-caking performance of Advance Coat™ and with the product quality of each delivery. We are happy to continue the cooperation with Stamicarbon and hope that Stamicarbon can continue delivering high-quality products,” the client said.