Achieve higher productivity and reliability with E-type material

The Challenge

High-pressure (HP) piping is often overlooked during inspection or maintenance as those are more difficult to perform in a timely and structured manner. But HP piping is exposed to the same process conditions and is therefore facing the same corrosion issues as HP equipment and can lead to catastrophic incidents in the plant if neglected.

Corrosion problems in piping can occur from the process and atmospheric sides of piping, such as atmospheric corrosion and corrosion under insulation (CUI). To preserve the integrity of piping and prevent failures, it is essential to pay attention to both.

Corrosion issues from the process side include:

- Active and passive corrosion in liquid phase

- Condensation corrosion in the gas phase

Atmospheric and CUI issues include:

- Overall corrosion

- Chloride stress corrosion cracking (SCC) under insulation or clamps

- Crevice corrosion at supports

Passive corrosion is incorporated in the design of piping, so it does not present a threat to its integrity. On the other hand, active corrosion occurs at very high rates in the absence of oxygen, reducing pipe wall thickness and potentially leading to failure.

Our Solution

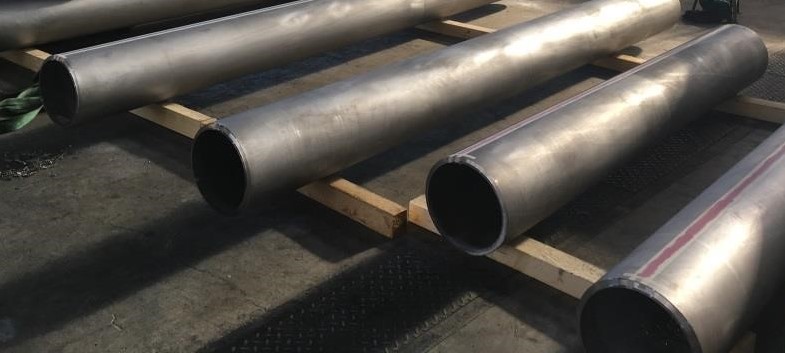

Piping and fittings made of E-type material solves the corrosion problems listed above.

The possibility of active corrosion in the absence of oxygen is eliminated, and equipment made of E-type material has high resistance/immunity to the other corrosion phenomena experienced in urea plants. On top of that E-type material has much higher mechanical strength than traditionally used materials, allowing to reduce the pipe thickness resulting in lower investment costs.

With E-type HP piping you can:

- Improve flexibility

- Increase inspection intervals

- Lower the need for maintenance and repairs

- Improve plant safety

- Lower CAPEX and OPEX

- Achieve higher plant yields

We offer full lifecycle support to our clients for HP piping, including:

- Piping lifetime assessment (LTA), based on risk-based inspection (RBI) methodologies, an inspection strategy to identify potential risks related to HP piping in a urea plant

- Piping replacement in E-type material equipment, including on-site measurements, optimized piping layout, detailed engineering, piping stress calculation according to international standards, piping (re-)design and piping material supply based on detailed MTO

- On-site welding, training and supervision, including training and certification of welders who weld E-type materials

Why E-type Material?

E-type material (formerly known as Safurex) is one of the most advanced Stamicarbon equipment. This is a family of high-alloyed duplex (austenitic-ferritic) stainless steels developed to withstand the corrosive environments in all urea synthesis process applications.

This material eliminates active corrosion and lowers passive corrosion rates significantly compared to the austenitic stainless steels traditionally used for piping in urea plants.

The superior strength properties of E-type equipment allow for the use of pipes with smaller wall thickness (lower schedule).

In some cases, it is also possible to replace an existing pipe with a smaller pipe size in E-type material equipment, further reducing costs.

In any case, the internal diameter will increase and create more throughput by replacing a 316L UG (Urea Grade) HP pipe in E-type material of the same size but with a lower pipe schedule.

Other benefits of using E-type material for HP piping and fittings include:

- Resistance to condensation corrosion and intergranular corrosion (SIIC)

- Significantly lower sensitivity to SCC

- Eliminating the need for oxygen passivation

- Easy weldability

- Longer HP piping lifetime

- Cost savings thanks to reduced weight and thickness

- Reduced risk of shutdowns due to unplanned maintenance

- Higher plant safety and reliability

Since 2003, E-type materials have been specified as the standard materials for all high-pressure equipment and piping in Stamicarbon urea plants. Their superior mechanical properties and corrosion resistance make them the perfect choice of stainless steels for HP piping and fittings.

Contact us if you would like to know more about optimizing your plant operations with Stamicarbon equipment.