Monitor leaks to ensure plant safety

Having a state-of-the-art leak detection system (LDS) in urea plants is not an option; it is a necessity.

Severe conditions in the synthesis section of the plant constantly affect the protective liners that cover the carbon steel high-pressure equipment.

Over time, these liners become thinner, potentially causing ammonium carbamate to leak and leading to corrosion.

In case of a leak, a hazardous situation can happen, placing in danger your staff, equipment, and the surrounding environment. But this can be prevented with a reliable leak detection system.

Why Leak Detection Monitoring?

The loose liners protecting the carbon steel vessel, with time, become vulnerable to the following types of corrosion:

- Crevice corrosion

- Corrosion in the Heat Affected Zones (HAZ)

- Condensation corrosion

- Fatigue crevices

If there is a leak in the protective lining and ammonium carbamate reaches the carbon steel vessel, active corrosion takes place at a rapid speed and plant operations must be stopped immediately.

Timely detection of a liner leakage can not only reduce damages to equipment but, most importantly, protect the health and safety of plant staff.

Benefits of a Reliable LDS

A proven industrial LDS is critical for ensuring the safe operation of lined high-pressure equipment. The system monitors the lining continuously and triggers an alarm when detecting a leak, also indicating its location.

By installing an LDS, you get the following benefits:

- Use a single system for more than one piece of high-pressure equipment

- Monitor for leaks continuously

- Achieve a quick response time (under 60 minutes)

- Increase the lifetime of your high-pressure equipment

- Significantly lower repair costs, if any

- Reduce turndown period and production losses

A reliable system can update you continuously on the integrity of protective liners during everyday plant operations, although it does not replace a complete and careful inspection of liners during a normal turnaround.

Types of Leak Detection Systems

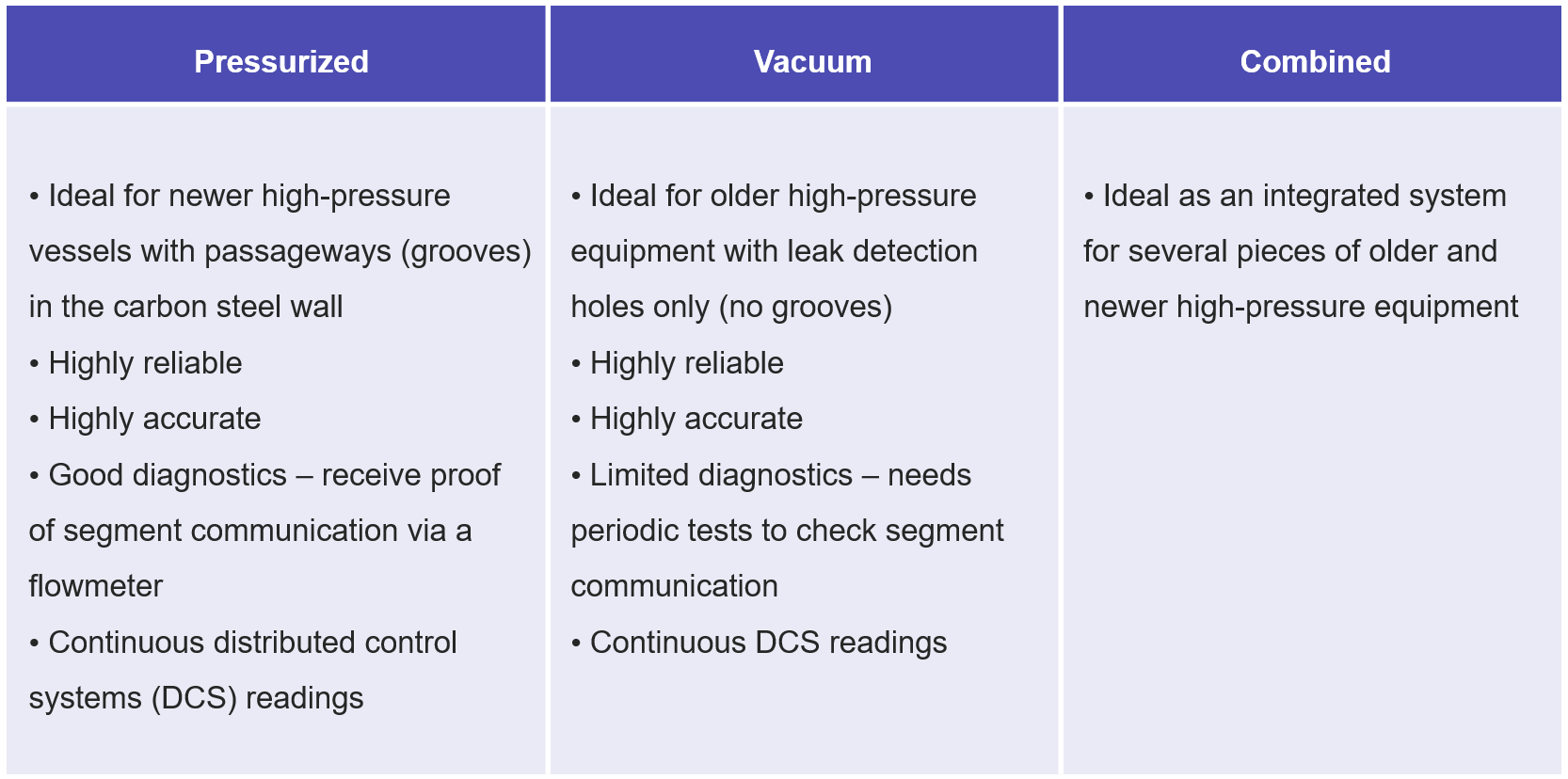

Choose between the three types of LDS we offer: Pressurized, vacuum, and Combined.

Stamicarbon recommends using a pressurized leak detection system for all high-pressure equipment with passageways (grooves).

Our pressurized LDS is easy to use and maintain, providing immediate flowmeter readings in case of a passageway blockage behind the liner, which is only possible to identify with periodic tests in vacuum or hybrid systems.

A pressurized system also prevents the risk of false alarms caused by ambient air containing ammonia entering the tubing in case of a tube leakage.

A leak detection system is crucial for safe plant operations, so it needs to be inspected regularly. And as the high-pressure equipment ages and its protective lining becomes thinner, a high-quality system becomes even more critical.

Our systems are compatible with both new and existing (older) high-pressure equipment. We can also provide additional services, including:

- Inspection of your current leak detection system

- Assistance with installation, commissioning, and start-up

- Training of operators and technicians

- Troubleshooting support

In the event of a leak, Stamicarbon can also help repair damaged equipment and perform equipment relining to replace corroded liners.

Contact us to receive more information about the most suitable LDS for your plant.