Technology Training Simulator for Stamicarbon’s Ultra-Low Energy urea process to be realized in Gemlik, Turkey

The Technology Training Simulator (TTS) will be used to train operators of the Gemlik Gübre’s urea melt and granulation plant in Gemlik, Turkey, planned to be in operation in 2023. With a capacity of 1640 mtpd urea and 500 mtpd UAN, the plant will be based on Stamicarbon’s LAUNCH MELT™ Ultra-Low Energy (ULE) urea process design that allows for energy saving unrivaled by any other known urea technology. This is already Stamicarbon’s fourth grassroots urea plant based on the ULE design, with three previously licensed plants located in China.

Safe and effective technology training

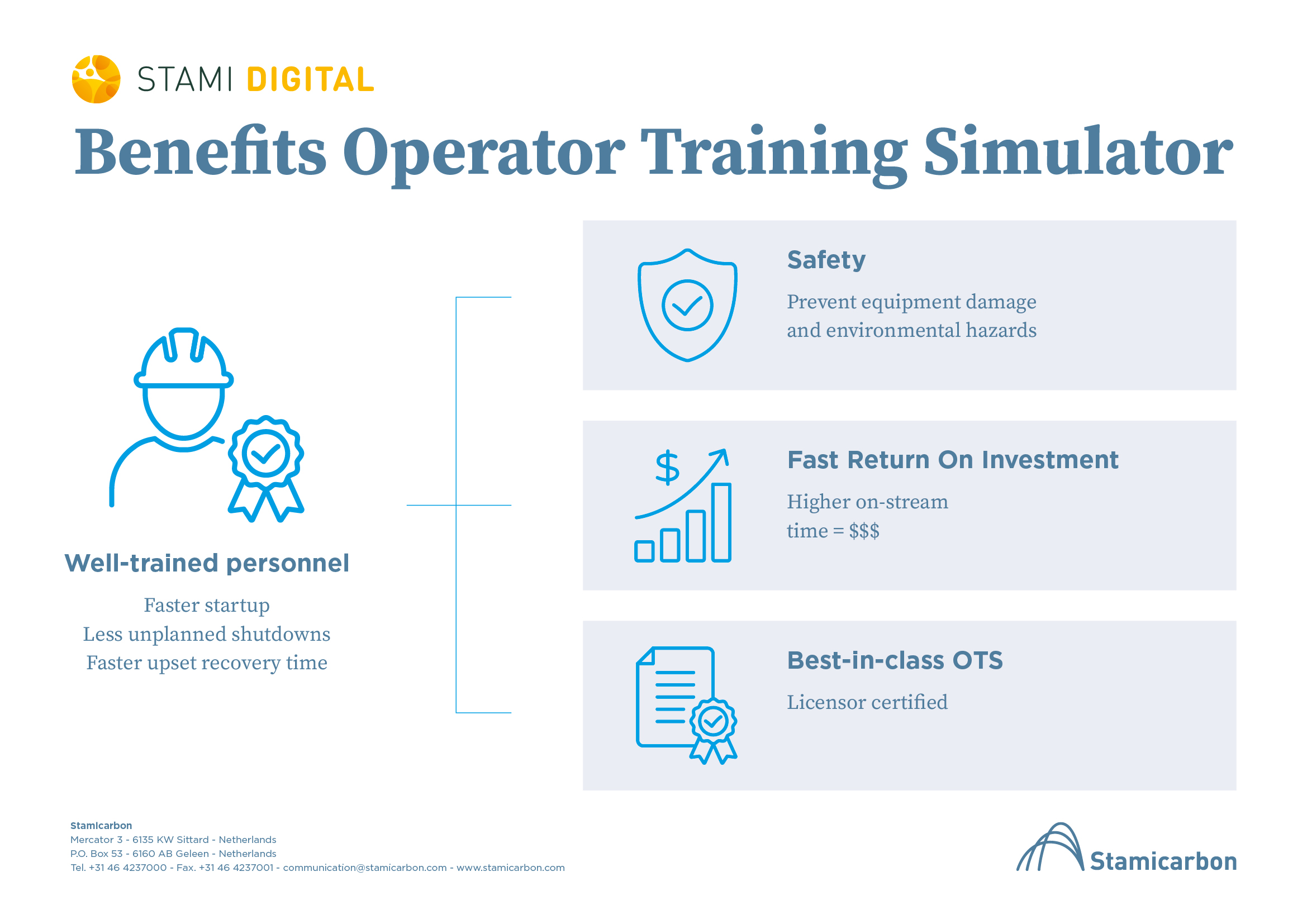

Stamicarbon’s high-fidelity TTS allows for efficient training of plant operators on start-up and shutdown procedures, day-to-day plant operations and various scenarios in the plant. In addition, it helps understand the dynamic behavior of the urea melt and granulation plant and simulates upset conditions in a digital environment to safely and effectively prepare operators for emergencies.

Stamicarbon’s standard TTS for the ULE process was already used to train operators of the first ULE urea plant in China to achieve a smooth and successful startup in February 2021.

The Gemlik Gübre’s TTS is tailor-made, with a high-fidelity real-time dynamic plant model accurately (accuracy > 98%) simulating the dynamic behavior of the plant.

“Chances of incidents occurring in the plant are low, but the potential consequences of even one failure should not be ignored – from safety, environmental, and financial perspectives. By having a TTS, plant operators receive better training and gain more knowledge about plant behavior, contributing to faster startup, faster recovery from plant upsets, higher on-stream time, increased plant safety, and environmental benefits (lower emissions), resulting in significant cost-savings while operating the urea plant,” said Emiel Mehlkop, Licensing Manager at Stamicarbon.

About Ultra-Low Energy technology

Stamicarbon’s LAUNCH MELT™ Ultra-Low Energy design is a breakthrough process technology that allows for heat supplied in the form of high-pressure (typically 20 – 25 bar) steam to be used three times instead of two. As a result, the steam consumption is reduced by about 35% and cooling water consumption by about 16%, compared to traditional CO2 stripping processes. The centerpiece of this technology is the ultra-low energy pool reactor, utilizing proprietary Stamicarbon Safurex® stainless steel with two heat exchanging tube bundles.

This technology lowers operating expenses (OPEX) substantially and offers significant environmental benefits by reducing energy consumption. The ULE design is not only suitable for new urea plants, but it can also be used as a powerful revamp tool for both CO2 stripping and conventional urea plants.