The Challenge

Mechanical strength is especially important when the product needs to be stored after being subjected to various handling operations.

Poor mechanical strength leads to disintegration and dust formation, which also increases the caking tendency. Improving the impact strength is important if the prills are handled multiple times.

The solution

During prilling, the impact of the prills on the prilling tower floor and the scraper's action form very fine urea dust. Some of this dust can be carried along with the rising air stream in the prilling tower.

Also, on collision with the descending urea droplets, the dust particles act as nuclei. If a droplet collides with several dust particles, the prill will ultimately consist of several randomly oriented crystals.

Because of the coherence between these irregular crystals, the prills have high impact strength. If the dust concentration in the rising air is low, the droplets do not collide with enough dust particles.

Urea droplets may become supercooled. Owing to crystallization from the supercooled phase, the weak prill modification is formed. Supercooling is the physical phenomenon whereby a substance remains in the liquid phase even though its temperature is below the crystallization temperature. The crystallization temperature of supercooled droplets can be as low as 90°C.

The absence of sufficient urea dust particles is imputable to the quantity of dust carried along with the rising air stream from the prilling tower bottom or by atmospheric conditions.

Due to the hygroscopic nature of urea, the urea dust particles will absorb moisture from the ambient air if the relative humidity of the air is higher than the Critical Relative Humidity (CRH) of the urea. At high humidity of the ambient air, the dust particles may absorb so much water that they pass into the solution and no longer act as nuclei.

Perill Impact Strengthener Design

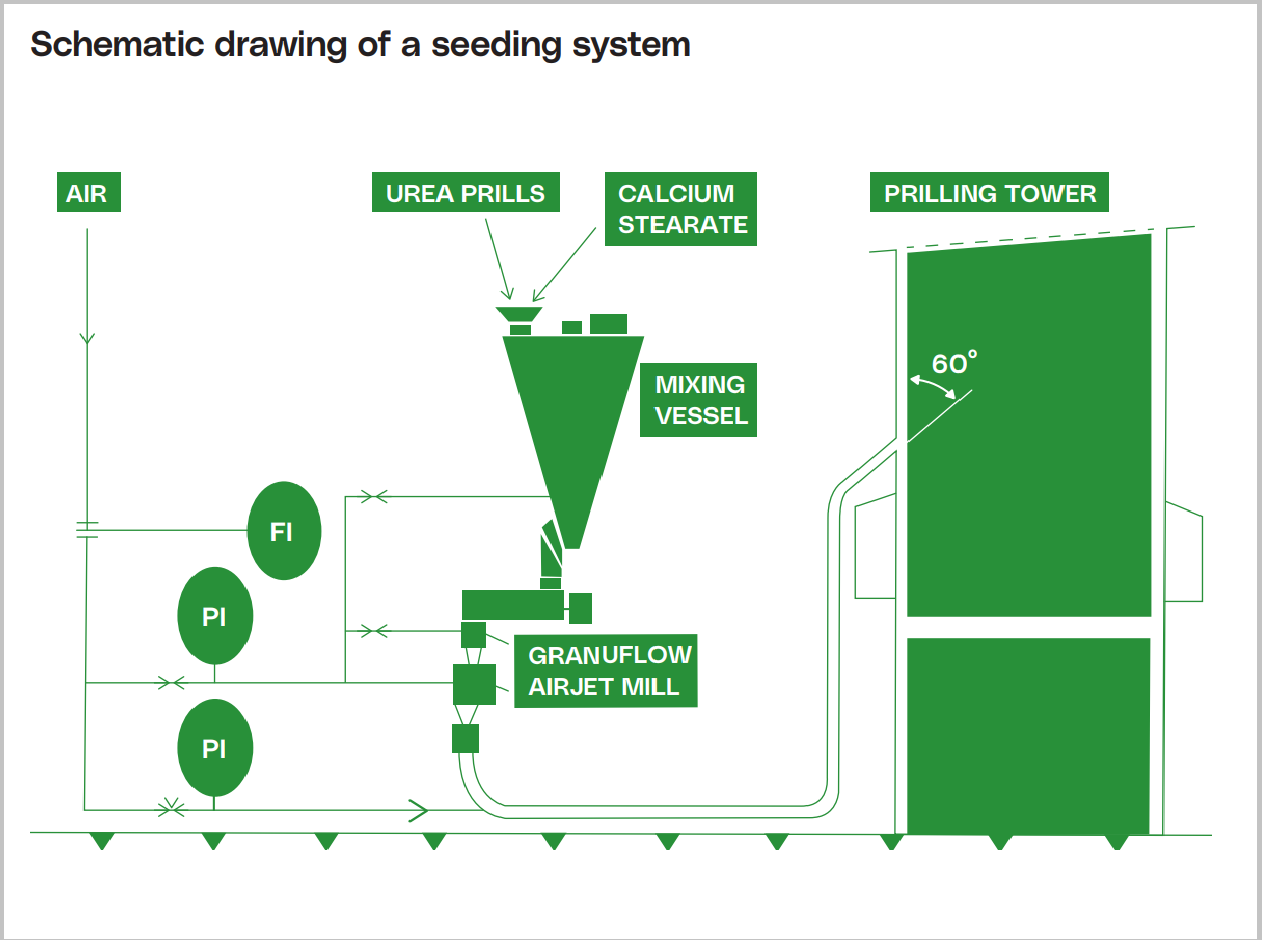

To overcome this, Stamicarbon offers a proprietary technology that enhances prill strength by restoring the natural crystallization process in the prilling tower.

Our solution introduces urea seeds, small particles that act as nucleation centers, directly into the tower. These particles collide with urea droplets, promoting the formation of multiple crystals within each prill.

This results in mechanically stronger prills, better resistance to impact, and a significant reduction in dust and product degradation throughout the supply chain.