N/C Meter

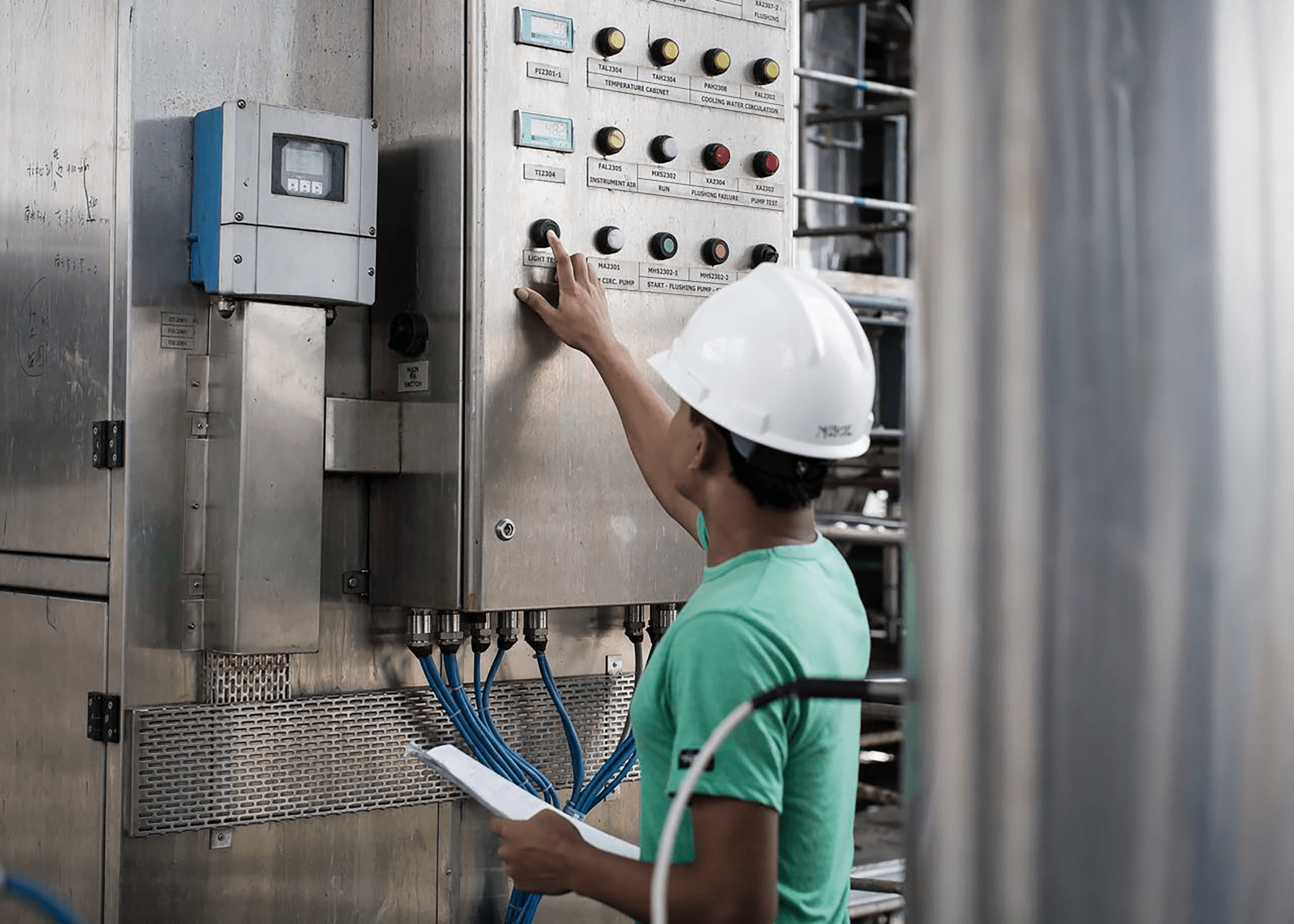

Automate N/C measurement for safe and reliable plant operations

A fluctuating nitrogen/carbon (N/C) ratio, due to the ambient temperature changes between day and night, is a common problem that can prevent a plant from operating at its maximum capacity.

In many cases, samples for determining the N/C ratio are taken manually, which can be dangerous and costly. But there is a safer and more reliable way to determine the N/C ratio.

N/C Meter, part of Advance Monitor™, provides real-time information of the actual N/C ratio of the synthesis, helping you to optimize and control your plant operations.

Why N/C Meter?

Knowing the real-time value of the N/C ratio allows adjusting the plant's operating parameters, which helps to achieve the highest urea reactor efficiency and gives the plant operator more control over the urea synthesis process.

Actual and frequent readings help in controlling the ammonia flow in a better way and achieving the optimal ratio of feed streams so that you can use available feedstock in the most optimal way.

This also allows for optimizing steam consumption and increased control over ammonia emissions, resulting in a more environmentally-friendly production process.

The automation of N/C measurement comes with several advantages, including the following:

- Increased safety, eliminating hazards to staff when taking manual samples

- Quick results, without the need for frequent laboratory tests

- Cost-savings thanks to limited need for maintenance, reduced laboratory spending, and improved plant efficiency

Having an industrial proven N/C metering system in place is even more critical during plant start-up when the measurements of the ammonia and carbon dioxide flows might not be reliable yet. That's why taking quick samples of the N/C ratio can help start the plant up quicker and easier.

How It Works

An N/C Meter continuously analyzes the liquid phase at the outlet of a urea reactor. It offers a proven and reliable solution to receive accurate N/C ratio readings in real time. In addition, automation of the process helps ensure higher and more stable urea production.

As a plant operator, you can control the stability of temperature and pressure in the reactor more easily and receive an indication of any undesirable conditions.

Keeping the N/C ratio closer to its optimal value continuously leads to a more stable operation of the synthesis and, subsequently, optimal performance of the entire plant.

With almost 75 years of expertise in designing and licensing plants and equipment for the fertilizer industry, Stamicarbon identifies various challenges of urea plants and designs solutions to tackle those.

We observed that by reducing variations of the N/C ratio in the urea reactor, it is possible to achieve the following:

- Lower steam consumption

- Lower ammonia losses

- Increase in urea production

Contact us for more information about our N/C metering system.