Achieve superior urea reactor lifetime with E-type material

The Challenges

Urea Reactor lifetime differs substantially between different technology concepts. To ensure a superior lifetime of the urea reactor in both Stamicarbon and non-Stamicarbon plants, we design urea reactors with equipment made of E-type material.

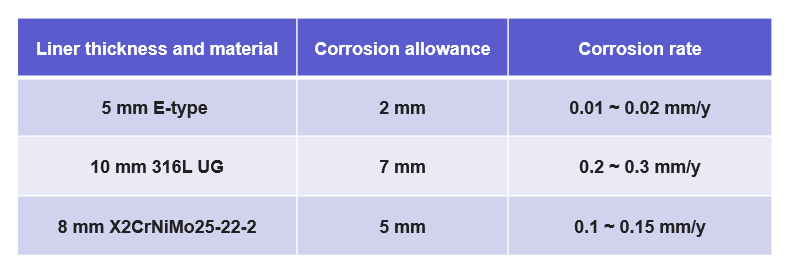

A thinner liner made of E-type material provides a significantly longer expected lifetime of the urea reactor compared to thicker austenitic stainless steel liner materials. Below, you can compare the corrosion allowance and corrosion rate in different materials and thicknesses:

Longer equipment lifetime can be achieved with a thinner E-type liner despite the harsh process (upset) conditions, such as, for instance, loss of passivation air or longer block-ins of the high-pressure (HP) synthesis up to a couple of weeks.

The Solution

Stamicarbon offers several solutions for the renewal of urea reactors:

- Replacement of the end-of-life urea reactor with a new urea reactor made of E-type liner and internals

- Partial relining of the existing (316L UG lined) urea reactor with X2CrNiMo25.22.2 or E-type liner material based on Stamicarbon relining philosophy, including welding and relining procedures developed by Stamicarbon

- Complete relining of a urea reactor (316L UG, X2CrNiMo25-22-2 or Titanium liner) with X2CrNiMo25-22-2 liner material. In certain cases, we can offer relining with liners made of E-type material.

- Revamping the existing reactor by adding additional volume, either using Stamicarbon E-type material or X2CrNiMo25-22-2 liner plates

- Improving reactor conversion of the existing urea reactor by installing E-type high-efficiency or Siphon Jet Pump (SJP) trays

- Improving the safety of the existing urea reactor by replacing the radioactive level measurement system with radar and implementing a state-of-the-art leak detection system

If you are unsure whether your urea reactor should be relined or replaced, contact our experts to help determine the best solution for your specific situation.

Our reactor design and materials are customized for different applications. We consider the design and material of the carbon steel shell and use low- or high-strength steels based on the client's requirements.

Stamicarbon offers a full scope of replacement for urea reactors, including all necessary instrumentation, such as:

- Radar level measurement

- Leak detection monitoring system

- Thermowells and thermocouples

- Pressure transmitters

We also offer replacement solutions for the adjacent piping in the HP synthesis section.

As a urea technology licensor, Stamicarbon is also able to calculate possible process improvements based on the new configuration of the reactor design and those can be contractually agreed upon as process guarantees at the battery limits of the reactor (e.g. conversion rate (%) or urea content (%)).

Advantages of the E-type Material Urea Reactor

Reactor trays have a proprietary design and are made from proprietary E-type material duplex steel.

Receive the following advantages:

- Reduced need for inspections and maintenance due to the high corrosion resistance of E-type material

- Longer lifetime of the urea reactor

- Improved reactor conversion by optimized design of the trays

- Increased plant safety with the possibility to use a radar level measurement device and the implementation of a state-of-the-art leak detection system

- Opportunity to increase block-in periods thanks to the resistance of E-type material to active corrosion

About Urea Reactor

The urea reactor is a vertical E-type material lined high-pressure carbon steel vessel. The mixture of ammonia and carbamate solution from the HP carbamate condenser or pool condenser, along with gaseous ammonia and CO2 from the HP stripper, enters the bottom of the reactor.

In the urea reactor, the conversion of ammonium carbamate into urea approaches its equilibrium. Meanwhile, the remaining reactants and converted products rise to the top and are transferred into the HP stripper in stripping urea plants or transferred to the medium-pressure (MP) / low-pressure (LP) section in conventional urea processes.

The purpose of the urea reactor is to provide a large volume to allow sufficient residence time for the reactants to reach equilibrium. This is needed because the conversion of carbamate into urea takes much longer than the formation of ammonium carbamate.

Urea Reactor Replacement in Non-Stamicarbon Plants

Stamicarbon offers reactors for all urea processes. Replacement of any HP vessel in urea synthesis is an opportunity to debottleneck the plant.

Therefore, we perform process plant assessments before replacing the HP equipment to identify what modifications should be addressed in the new vessel's design.

Contact us for more information about our urea reactors.