Optimize Your Plant

A fully optimized urea plant has an extended life, increased output and optimized energy efficiency, conforms to the highest safety standards and exceeds environmental regulations.

Our Advance series™ gives you a choice of products and services for increased optimal plant performance. The Advance series™ ensures the smooth and efficient operation of your urea plant in five areas.

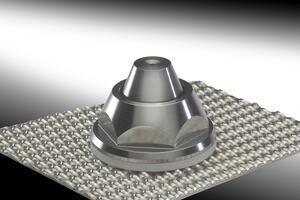

Stamicarbon Equipment

Urea industry processes take place at high temperatures and pressure. Ammonium carbamate is also highly corrosive. Therefore, the high-pressure (HP) synthesis equipment and parts have to be manufactured from strong, light and corrosion-resistant materials. The solution is E-type Material, specially aiming to eliminate corrosion in fertilizer plants.

E-type Product and Services

To ensure reliable operation and long-lasting results in our clients' urea plants we use advanced products made of E-type material.

Plant Maintenance Services

To ensure that your plant is always well maintained we offer a series of services in our Inspect, Design and Monitor product ranges.

Agile Response

To promote safe and uninterrupted operations of your plant, Stamicarbon offers equipment relining and repair as part of its Full Life Cycle Support services. In case of an emergency, our Agile Response Team is on call 24/7 to get you back to production. One of our experienced engineers will assess your emergency and form an emergency team to arrive at the plant site as soon as it can be arranged.

High-pressure equipment replacement

Read everything about our groundbreaking high-pressure equipment solutions for your plant.

Products and Services for Non-Stamicarbon Plants

Stamicarbon offers consultancy, products and services for non-Stamicarbon plants, optimizing the performance of urea plants and providing reliable solutions for sustainable plant operation.

Solutions for Producing Quality Urea

Stamicarbon can support you in maintaining and improving your product quality, so you keep meeting and exceeding your clients' expectations.

Optimizing Process Operations and Control

Stamicarbon offers a range of plant operation services to improve performance, production and energy consumption.

Staff Training & Support

We have developed training programs to keep you and your staff up to date. Who should attend our trainings?

- Urea melt plant operators

- Urea melt plant engineers

- Urea production managers

- E-type material welders

Our tailor-made trainings include:

- Operation & Technical

- Mechanical & Maintenance

- Simulator Training

HSE services & solutions

Operating a urea plant comes with an immense responsibility to protect your people, your assets, and the environment. In such a high-stakes environment, safety is not just a matter of compliance, it is the foundation of a sustainable and profitable operation

Full Life Cycle Support

Learn moreContinued support to urea producers worldwide throughout the entire lifetime of their plants, no matter at which stage their plant is.