The challenge

Nitric acid is an important chemical compound, with about 80% of total production dedicated to application in the fertilizer industry.

Now, the challenges are: How to design a nitric acid plant with maximum energy recovery?

How to lower the investment costs in a nitric acid plant, and how to meet even the most stringent environmental standards?

The solution

Stamicarbon Mono- and Dual-Pressure Nitric Acid Designs

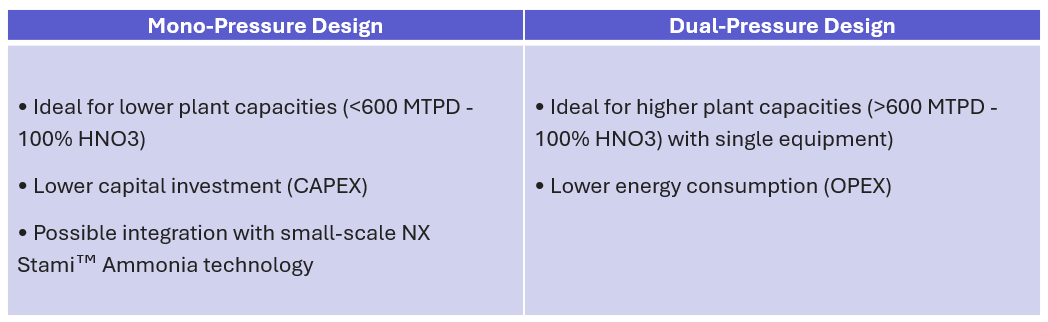

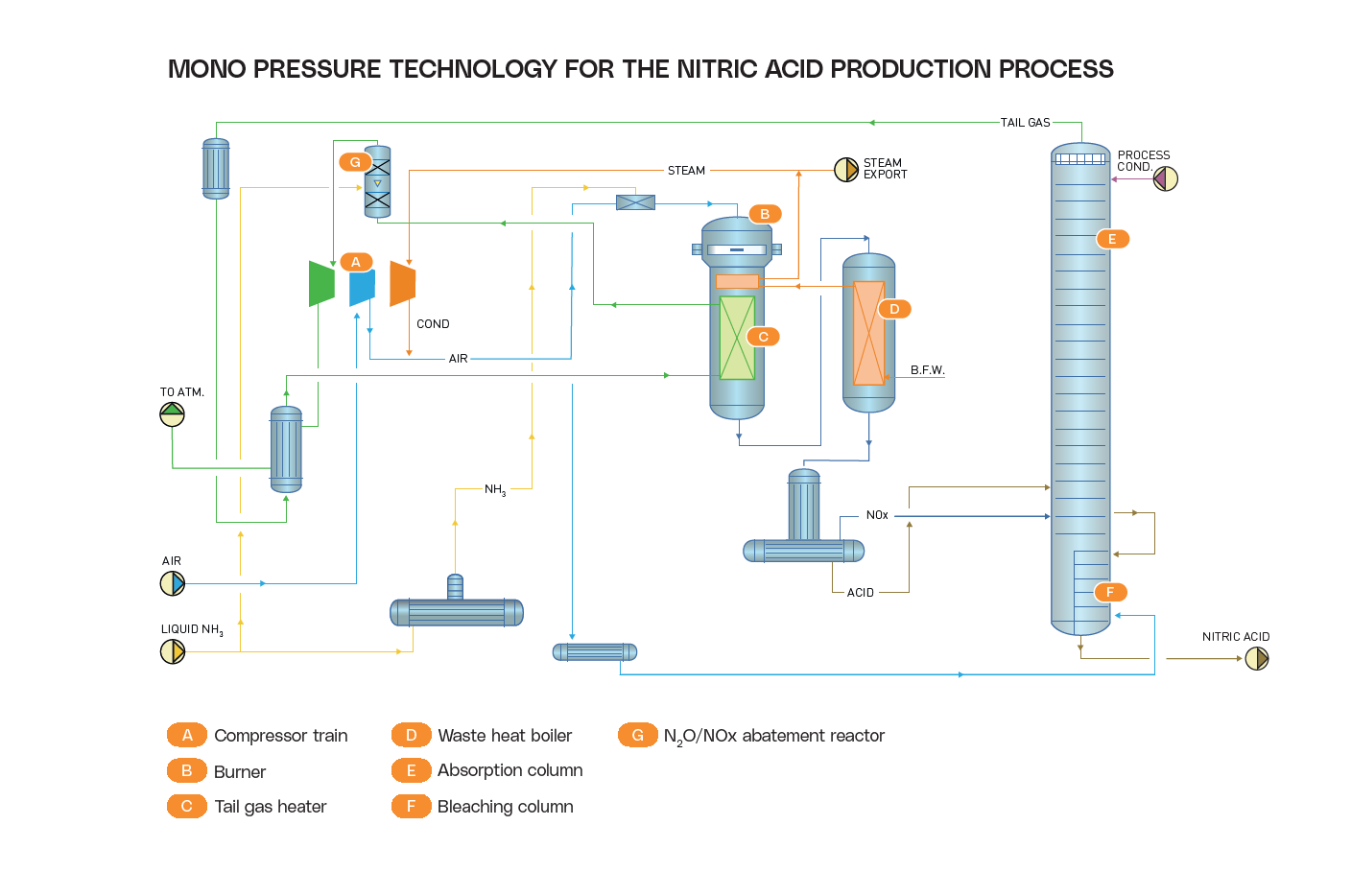

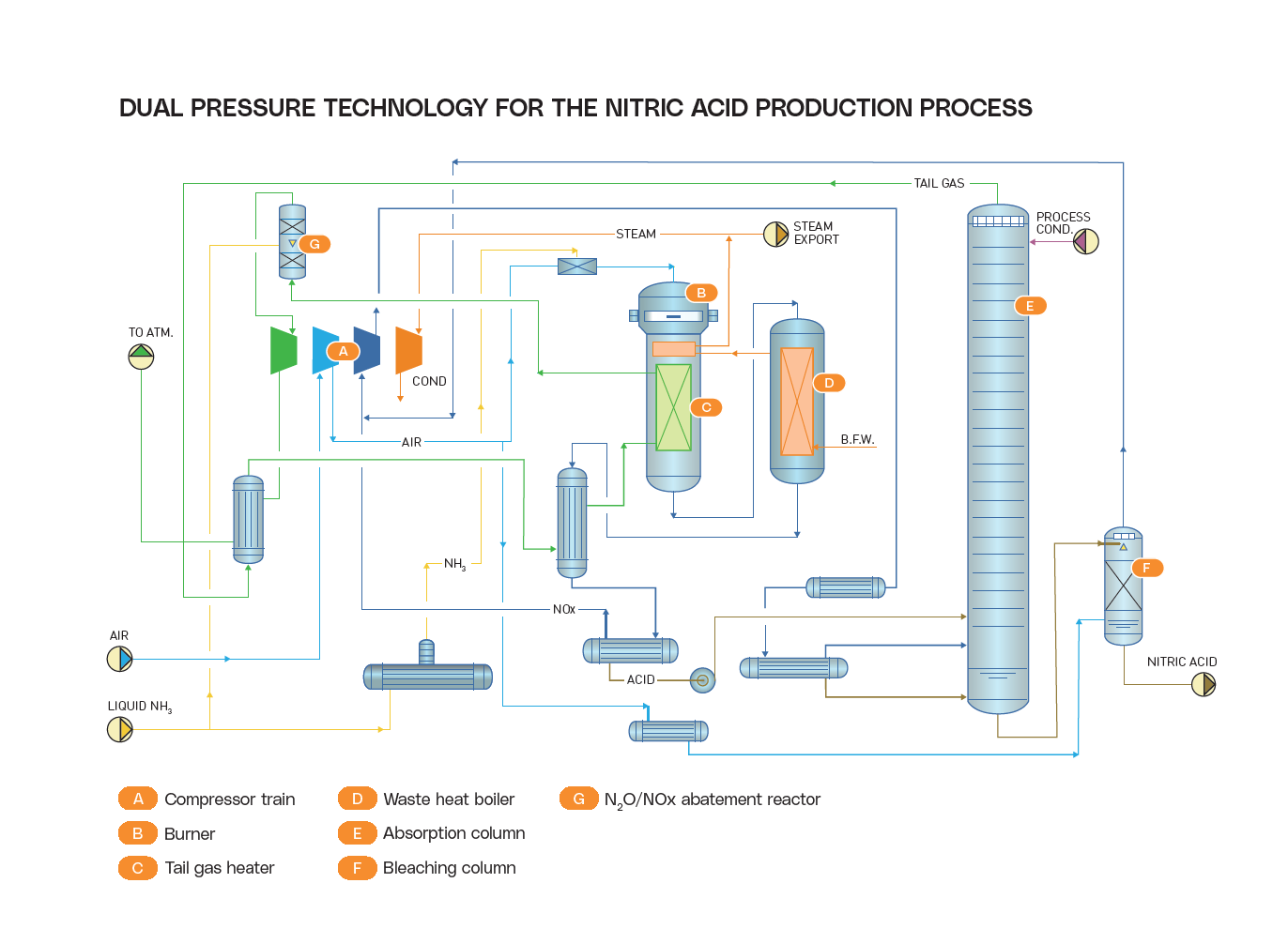

Stamicarbon offers mono- and dual-pressure nitric acid production processes for a wide range of plant capacities up to 600 MTPD (mono-pressure) or 2000 MTPD and above (dual-pressure).

Both processes are characterized by high tail gas temperature and designed for maximum energy recovery, reliable operation and minimal greenhouse gas emissions.

Stamicarbon Mono-Pressure Nitric Acid Design is ideal for lower plant capacities (<600 MTPD -100% HNO3). It has lower capital investment (CAPEX) and can integrate with small-scale NX Stami™ Green Ammonia technology.

Stamicarbon Dual-Pressure Nitric Acid Design is ideal for higher plant capacities (>600 MTPD- 100% HNO3) with single equipment. This technology also provides lower energy consumption (OPEX).

To learn more about Stamicarbon mono- and dual-pressure nitric acid process, download the brochure. Download

Advantages of NX Stami™ Nitric Acid

Stamicarbon's design significantly reduces the total cost of ownership by maximizing your plant's energy recovery and extending the equipment's lifetime. By choosing NX Stami™ Nitric Acid technology, you receive:

Lowest energy consumption for nitric acid production

The main feature of the Stamicarbon nitric acid process is the position of its third tail gas heater. Its location in the ammonia burner vessel allows tail gas temperatures of 480°C, which has several advantages:

- Nitrous oxide decomposition without the addition of an external agent like natural gas

- Higher power generation in the expansion turbine

- Extra heat recovery step before releasing the tail gas into the atmosphere

- Lower steam consumption of the compressor train and thus higher steam export

Operational safety

Safety is the number one priority for Stamicarbon when designing a nitric acid plant, just as it is for all our technologies. During plant start-up, ammonia slippage can increase the risk of forming explosive ammonium nitrate and ammonium nitrite in the low-pressure cooler condenser and the first compartments of the oxidation/absorption column. Stamicarbon's latest design is characterized by accurate control of the process to minimize ammonia slippage and additional safety measures to prevent unsafe situations during start-up.

Low emissions

Nitrogen oxides (NOx) and nitrous oxide (N2O), contained in the off-gas from nitric acid production, are harmful to the environment and contribute to acid rain, the greenhouse effect, and ozone layer depletion. Stamicarbon's solution, applicable to both new and existing plants, is a tertiary abatement system featuring a high-temperature reactor with Fe-zeolite catalyst. This proprietary technology is designed to efficiently remove both N2O and NOx in a single unit, meeting today's strict emission standards while optimizing capital investment and operational efficiency. Leveraging decades of experience in nitric acid technology, Stamicarbon can design a reliable, tailor-made tertiary abatement system for every type of nitric acid plant technology, process conditions, and emission requirements.

Listen to our podcast about Stamicarbon tertiary abatement system and its benefits. Listen to Podcast

Corrosion prevention design

The nitric acid process is highly corrosive, with the main corrosion problems caused by the acid condensation/re-evaporation effect. Stamicarbon's design carefully selects process parameters to minimize this effect and prevent corrosion. Stamicarbon's running reference plant (built in 1989) has been in operation for more than 30 years with no major corrosion issues. Furthermore, no proprietary materials are required in an NX Stami™ Nitric Acid Design, further reducing costs.

Stamicarbon's running reference plant (in operation since 1989)

Tailor-Made Nitric Acid Plant

Stamicarbon offers flexibility in creating a tailor-made solution for your nitric acid plant. Our technologies can be combined with the producer's technology, achieving optimal results. All engineering services can be sourced locally to lower investment costs.

A nitric acid plant can also be offered as an integrated solution within a larger complex for UAN production, including a nitric acid plant, urea solution plant, ammonium nitrate solution plant and UAN mixing plant.

Stamicarbon offers full life cycle support for nitric acid plants. Our capabilities go beyond designing new plants; we can provide mechanical support, troubleshooting and additional services like:

Proven, Reliable Technology

Since the 1930s, Stamicarbon has licensed a range of nitrate technologies and designed over 40 nitric acid plants worldwide. Stamicarbon plants are renowned for their safety, reliability and best-in-class mono- and dual-pressure nitric acid technology. We guarantee steam export, cooling water consumption, acid quality, and ammonia consumption.

Contact us to learn more about the possibilities for your plant.

FAQ

How can I reduce energy consumption in my nitric acid plant?

Stamicarbon’s Nitric Acid technology is designed for maximum energy recovery, primarily through the unique positioning of the third tail gas heater. This results in the lowest energy consumption and higher steam exports, significantly reducing your plant's operational expenditure (OPEX).

Is it possible to reduce the total cost of ownership (TCO) in a plant?

Yes, Stamicarbon Nitrates design reduces total cost of ownership (TCO) by maximizing energy recovery, extending equipment lifetime, and preventing corrosion.

Also, this technology doesn’t require proprietary materials, which helps to keep investment and maintenance costs low.

Can I integrate Nitric Acid production into other fertilizer production lines?

Yes, the nitric acid plant can be offered as an integrated solution within a larger complex for UAN (Urea Ammonium Nitrate) production, combining the nitric acid plant with urea solution, ammonium nitrate solution, and UAN mixing plants.

How can I reduce the risk of corrosion in a nitric acid plant?

Nitric acid processes are highly corrosive. However, Stamicarbon's design carefully selects process parameters to minimize the acid condensation/re-evaporation effect, the main cause of corrosion. An example is a plant with the Stamicarbon design that has been operating for over 30 years without major corrosion problems.

What safety solutions are available to prevent hazards in nitric acid plants?

Safety is paramount, and in our latest design, we have provided accurate process control to minimize ammonia slippage during start-up. This design prevents the formation of explosive ammonium nitrate and ammonium nitrite, ensuring reliable and secure operation.

How can I ensure that my nitric acid plant complies with NOx and N2O emission standards?

A reliable and advanced solution is adding a tertiary abatement system to drive more efficient and more sustainable nitric acid production. It features a high-temperature reactor with an Fe-zeolite catalyst. This single unit efficiently removes both NOx and N2O, ensuring your plant meets the most stringent environmental regulations.

Stamicarbon NA's design allows you to use a tertiary abatement system, ensuring your plant complies with global standards.

Listen to our podcast and learn more about tertiary abatement systems.

How do I decide between Stamicarbon’s Nitrates technologies?

Choose the design based on plant size, CAPEX and OPEX. We offer two proven designs:

- Mono-Pressure Design: Ideal for lower capacities, up to 600 MTPD, with lower capital investment (CAPEX).

- Dual-Pressure Design: Ideal for higher capacities, >600 MTPD and above, offering the lowest energy consumption (OPEX) for large-scale production.

Can I receive customized nitric acid technology based on my plant's specific needs?

Yes, Stamicarbon offers tailor-made solutions and flexibility to combine our technology with your existing systems. All engineering services can be sourced locally to lower investment costs and ensure the design meets your specific process conditions.

We also provide full life cycle support that includes mechanical support, troubleshooting, plant optimization services, plant inspections, equipment replacement, revamp studies, and Technology Training Simulator.