Stamicarbon equipment introduced in non-Stamicarbon CO2 stripping process

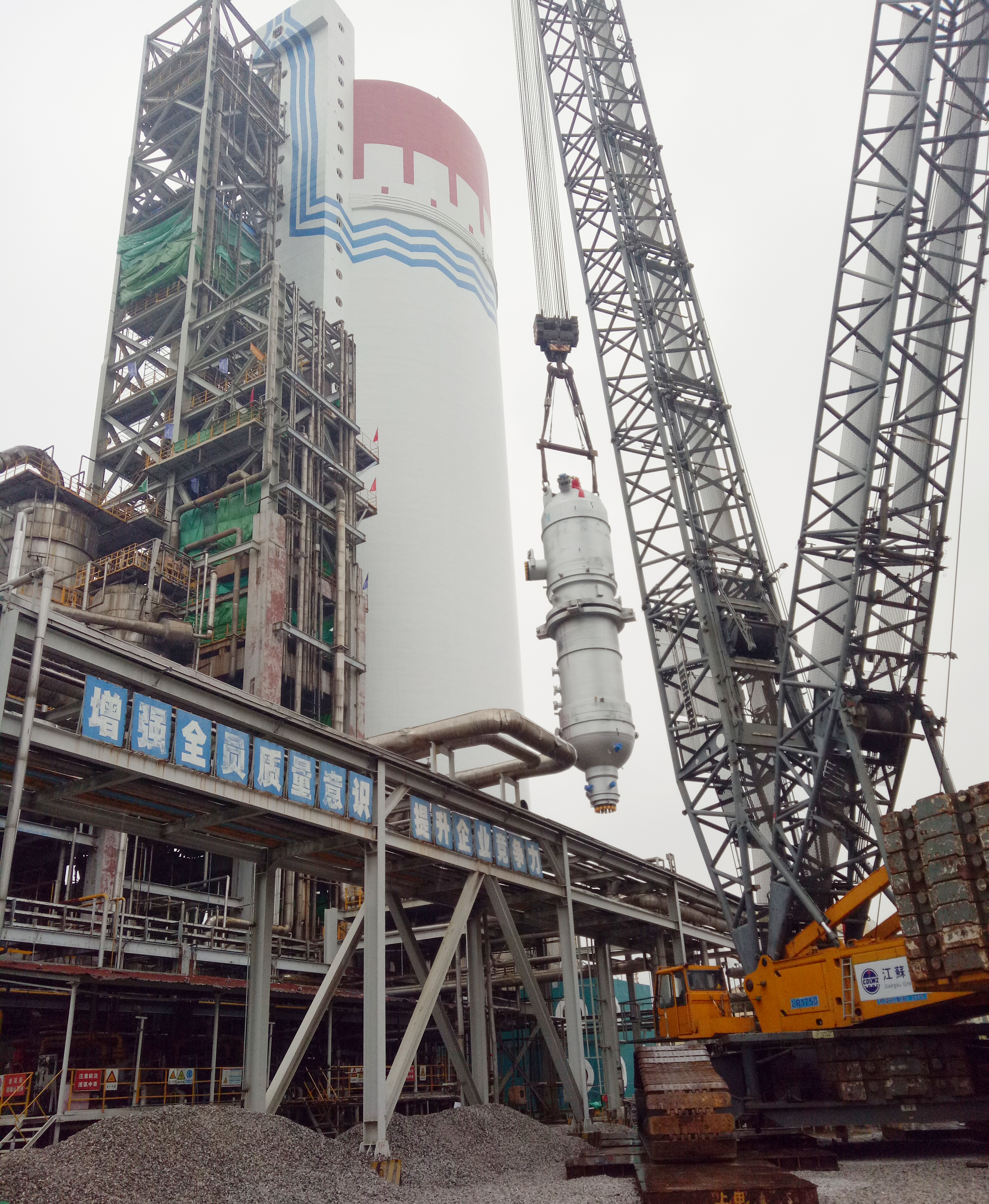

Stamicarbon delivered two high-pressure carbamate condensers and a high-pressure stripper for Weihua Group’s urea plant in Weinan, Shaanxi province in China in October 2020, marking the introduction of Stamicarbon equipment made from Safurex® for the non-Stamicarbon CO2 stripping process.

Stamicarbon delivered two high-pressure carbamate condensers and a high-pressure stripper for Weihua Group’s urea plant in Weinan, Shaanxi province in China in October 2020, marking the introduction of Stamicarbon equipment made from Safurex® for the non-Stamicarbon CO2 stripping process.

According to the article published on the client’s website in December 2021, an expert group investigated the material and corrosion properties of Safurex®, along with the economic benefits it brings, such as reducing the amount of material and equipment weight, and extending equipment lifetime. In the article, it is also mentioned that the expert group discussed the feasibility and compatibility of Stamicarbon equipment in non-Stamicarbon CO2 stripping process conditions and its process requirements. It was concluded that the application of Safurex® for the new high-pressure equipment can improve the overall plant reliability and OPEX.

“The client decided to purchase new equipment from Stamicarbon because of our comprehensive know-how and experience in urea process, as well as superior mechanical strength and corrosion resistance of Safurex® materials,” said Juan Lian, Sales & Solutions Manager at Stamicarbon. “We’re confident that the new equipment made from Safurex® will help our client improve plant reliability and reduce operating costs and services as another reference demonstrating the added value of Stamicarbon Equipment in non-Stamicarbon plants.”

With the application of Safurex®, the existing equipment design of the original licensor was optimized to achieve maximum corrosion resistance and a long lifetime of the high-pressure vessels. Moreover, the high-pressure stripper features liquid dividers in Safurex® Degree°, which improves their resistance to corrosion, especially cross-cut end attack, and extends the anticipated lifetime of the dividers.

The client commented: “Three pieces of Safurex® equipment have been put into operation for a year, and the plant has been running smoothly. We are planning to have a turnaround in 2022 and we will execute the first inspection on these vessels. We will keep Stamicarbon closely informed about the performance of Safurex® in our plant.”