The Challenges

The urea production process operates under extreme conditions of high temperature and pressure, requiring the condensation of ammonium carbamate as an intermediate compound. This leads to highly corrosive circumstances unless proper alloys are applied and passivating conditions are created.

Other fertilizer processes, such as Nitric Acid and Ammonia, also have specific process conditions. Addressing these challenges requires advanced materials and high-quality equipment capable of withstanding such aggressive environments while delivering long-term reliability and efficiency.

The Solution

Stamicarbon continually advances its material and high-pressure equipment portfolio to meet modern fertilizer production needs, delivering superior performance throughout a plant’s lifecycle. Regardless of the licensor, our E-type equipment ensures efficient, reliable operations with minimal environmental impact for grassroots plants and revamp projects.

Engineered for Critical Conditions

In the 1990s, Stamicarbon, in partnership with Sandvik (now Alleima), revolutionized urea production equipment by developing Safurex®. Safurex (now available as E-type material), is a proprietary super duplex stainless steel.

This material was specifically designed to eliminate corrosion in fertilizer plants. It effectively combats active ammonium carbamate corrosion, chloride-induced stress corrosion cracking, and other challenges unique to high-pressure urea synthesis equipment.

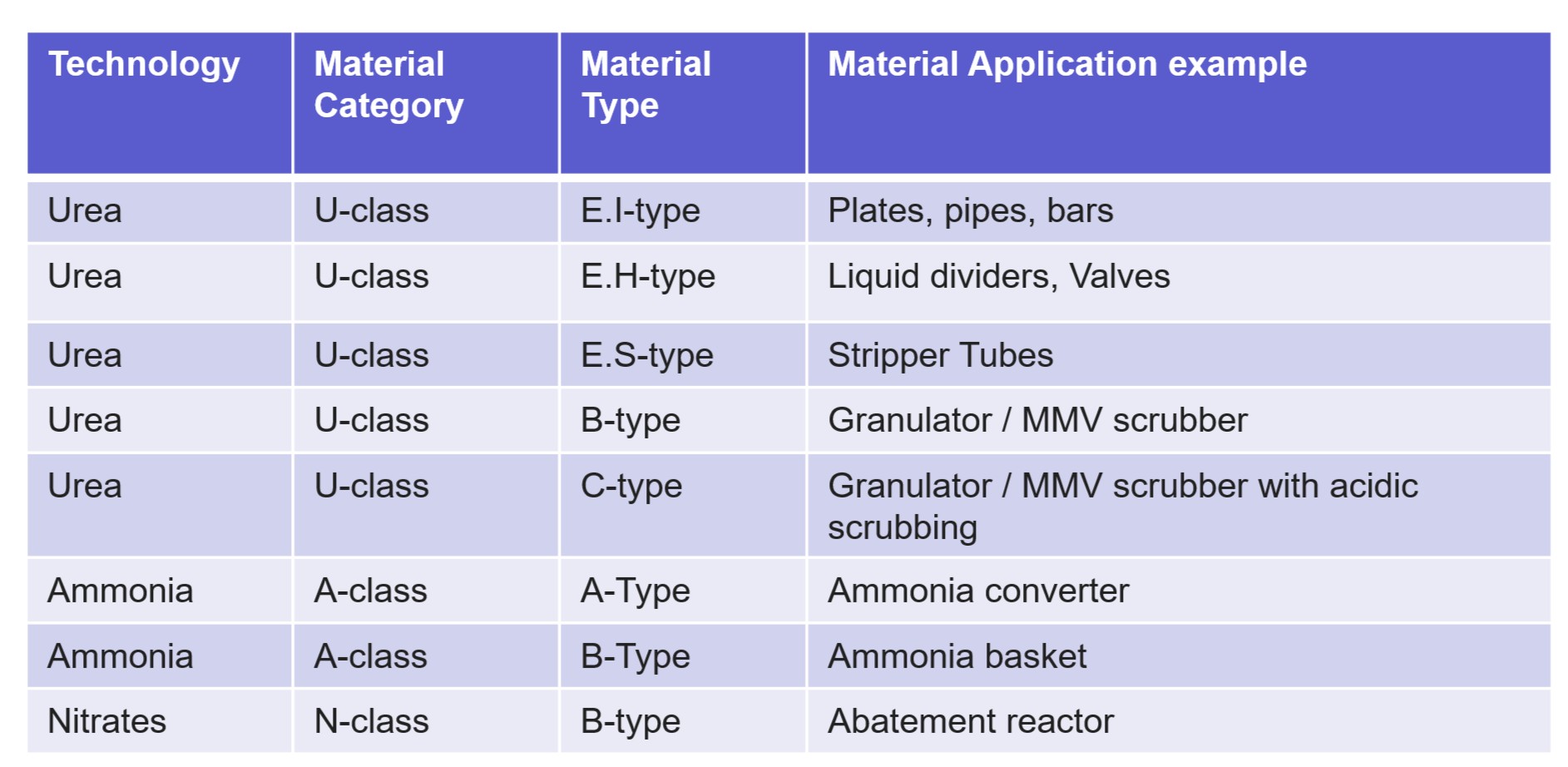

Below you can see different variations of E-type material and their applications.

Customized for Your Plant

As Stamicarbon has expanded beyond urea in recent years, the need for different materials for different applications has increased. With decades of material science expertise, we deliver durable, corrosion-resistant solutions that withstand time and environmental stress.

Different processes require different materials, which is why we use Urea, Ammonia, and Nitrogen-class materials. In some parts of the process, a more specific material category is needed. Our materials are grouped into three classes, tailored for applications across the nitrogen fertilizer industry.

U-class:

Designed for urea applications, with particular tailoring to high temperature/pressure and corrosive environments, such as in urea synthesis equipment.

• High-Pressure Strippers: Efficiently recovering ammonia and carbon dioxide while maintaining exceptional durability.

• High-Pressure Carbamate Condensers: Designed for energy-efficient heat exchange.

• Urea Reactors: Featuring high-efficiency trays and U-Class steel internals for maximum conversion efficiency.

• High-Pressure Piping and Valves: Engineered for reliability in extreme operating conditions.

• Liquid Dividers and Mixing Tees: Optimized for uniform performance and reduced operational complexity.

N-class:

Developed for nitrate applications, with particular tailoring to corrosive environments.

• Tertiary abatement reactor

A-class:

Tailored for ammonia applications, with particular tailoring to high temperature and embrittling environments, such as in ammonia converters.

• Ammonia converter

• Ammonia Basket

This diversity allows us to offer tailored solutions for specific process needs, enhancing the efficiency and reliability of fertilizer production. We maintain solid control over our supply chain, partnering with top-tier fabricators and performing rigorous quality checks at every stage to ensure equipment meets the highest standards.

Full Life Cycle Support

Besides equipment, Stamicarbin offers full life cycle support to producers, including plant troubleshooting and equipment inspections. We also provide 24/7 support to address unexpected emergencies like unplanned shutdowns.

Extend the lifespan of your plant’s equipment

Interested in extending the lifespan of your plant’s piping and optimizing the inspection process? Listen to the podcast below or watch it on YouTube, where Kirk Ofei, materials & corrosion specialist at Stamicarbon, highlights the crucial role of corrosion maintenance in prolonging the lifespan of equipment.